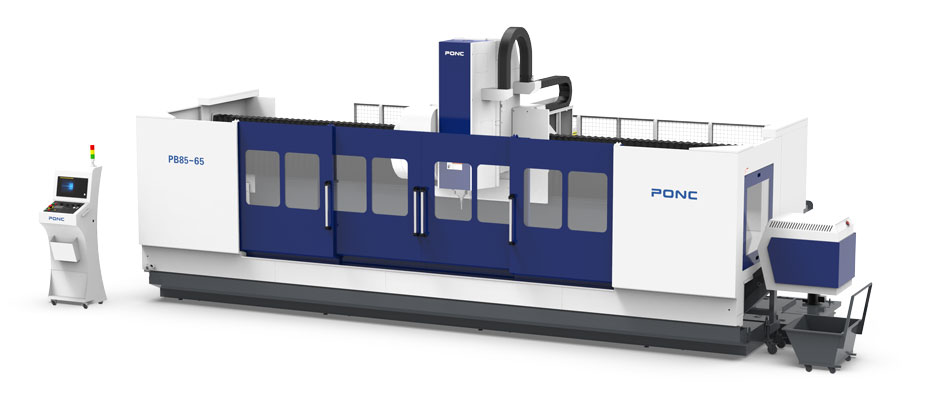

The Journey of PONC Profile Machining Centers

December 03, 2025

Amidst the wave of transformation and upgrading in China's manufacturing industry, one company has consistently focused on technological breakthroughs and innovative applications in the field of profile machining—PONC. From industrial aluminum to special materials, and from civilian applications to military use, PONC has forged a unique path as an expert in profile machining.

Industrial Aluminum: The Starting Point of Precision Breakthrough

PONC's technological journey began in the foundational and critical field of industrial aluminum machining. With the rapid development of China's manufacturing industry, industrial aluminum has found increasingly widespread applications in sectors such as rail transit, new energy vehicles, and electronic equipment, demanding higher requirements for machining accuracy and efficiency.

Addressing pain points in traditional aluminum machining, such as high deformation, low precision, and low efficiency, PONC's R&D team conducted systematic technological research. They deeply analyzed the material characteristics of aluminum alloys and, targeting their moderate hardness but susceptibility to deformation, developed specialized fixture systems and damping devices, effectively controlling material deformation during machining.

Simultaneously, PONC innovatively integrated high-precision sensors and real-time compensation systems into its machining centers, achieving automatic detection and correction of machining errors. This technological breakthrough not only elevated the precision of aluminum machining to new heights but also significantly improved production stability and product consistency, earning the trust of numerous industrial customers.

Auxiliary and Other Alloy Materials: Expanding the Technological Matrix

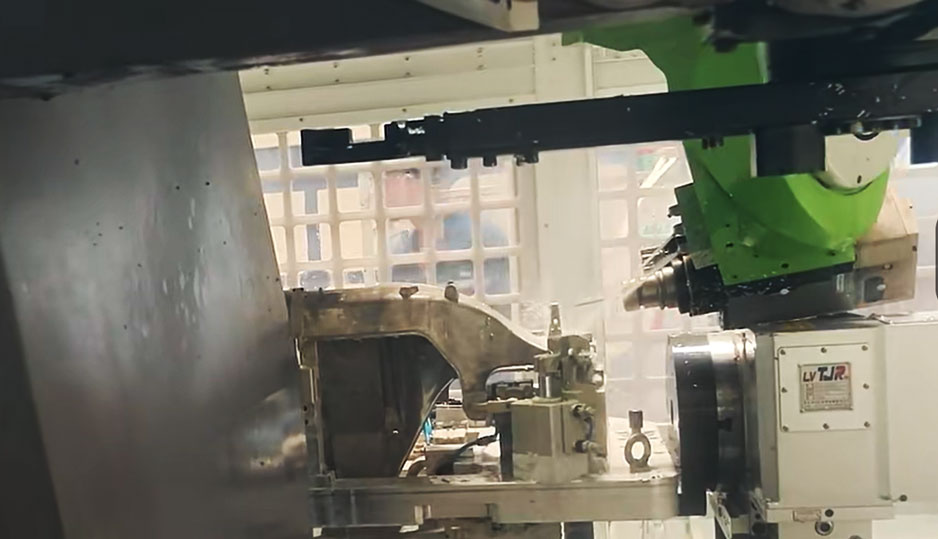

After achieving breakthroughs in the field of industrial aluminum, PONC shifted its focus to a broader range of material machining. From common auxiliary materials to various metal materials such as stainless steel, copper alloys, and magnesium alloys, PONC began constructing a comprehensive material machining technology matrix.

Addressing the physical properties and machining challenges of different materials, PONC developed a series of specialized machining solutions:

For high-hardness materials like stainless steel, it developed high-rigidity machine tool structures and specialized tool systems.

For high-thermal-conductivity materials like copper alloys, it optimized cooling systems and cutting parameters.

For flammable materials like magnesium alloys, it designed explosion-proof safety systems and specialized chip removal solutions.

The technological accumulation during this phase enabled PONC to develop the capability for multi-material协同 machining, allowing it to provide customers with cross-material, one-stop machining solutions, greatly enhancing production flexibility and efficiency for clients.

Military Special Materials: Scaling the Technological Peak

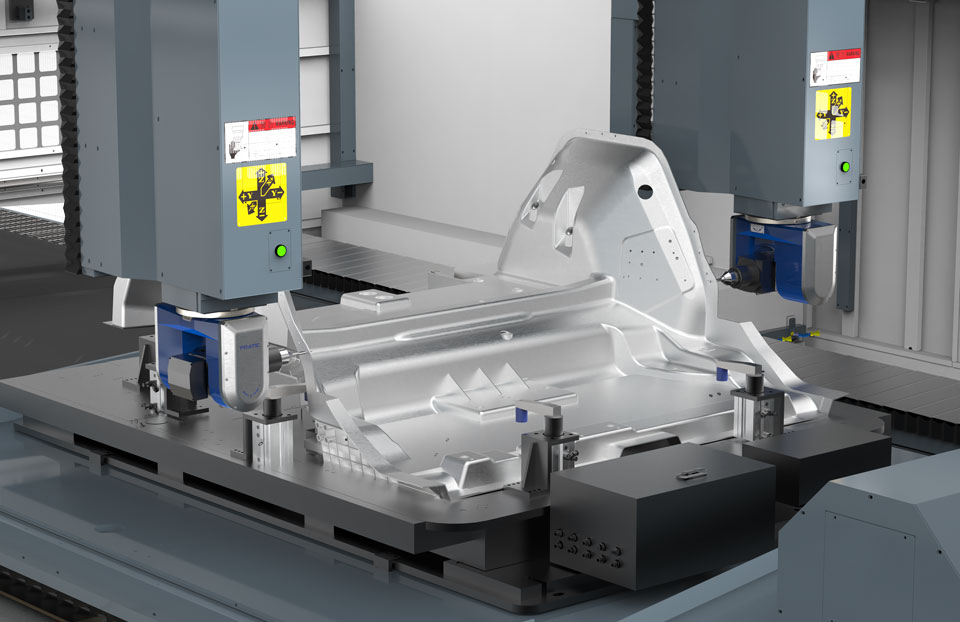

The areas that truly test a company's technological prowess are often the most challenging. Building on the increasing maturity of civilian material machining technology, PONC began to tackle the technological high ground of military special material machining.

Special materials used in military equipment—such as titanium alloys, high-temperature alloys, and composite materials—pose significant challenges in machining, including high difficulty, stringent precision requirements, and complex processes. The machining quality of these materials directly affects the performance and reliability of defense equipment, placing extremely demanding requirements on machining equipment.

PONC rose to the challenge, forming a dedicated R&D team composed of materials scientists, mechanical engineers, and military experts. After years of technological, PONC achieved a series of breakthrough results in the field of special material machining:

Breakthrough in Titanium Alloy Machining Technology: Addressing the challenges of titanium alloys, such as high strength, poor thermal conductivity, and severe work hardening, PONC developed low-speed, large-depth-of-cut machining techniques. Combined with high-pressure cooling systems and specialized tools, this effectively controlled cutting temperatures, extended tool life, and ensured machining quality.

High-Temperature Alloy Machining Solutions: For high-temperature alloys commonly used in aerospace engine components, PONC designed multi-axis linkage machining centers and adaptive control systems, achieving high-precision machining of complex curved surfaces and meeting the extreme performance requirements for parts in the military sector.

Specialized Equipment for Composite Materials: To address machining difficulties with carbon fiber and other composite materials, such as susceptibility to delamination and burring, PONC developed ultrasonic vibration-assisted machining systems, significantly improving machining surface quality and reducing material damage.

PONC understands that becoming a true expert in the profile industry requires more than just providing high-quality equipment. Therefore, the company has built a service system covering the entire equipment lifecycle:

Pre-sales Process Consultation: Providing personalized process design based on customer material properties and product requirements.

In-sales Technical Support: Offering equipment installation and commissioning, operator training, and process optimization services.

Post-sales Rapid Response: Establishing a nationwide service network to provide 24/7 technical support and rapid maintenance services.

Continuous Process Upgrades: Conducting regular customer follow-ups to provide process optimization suggestions and equipment upgrade plans.

This comprehensive service model has enabled PONC to form close cooperative relationships with customers, truly becoming an integral part of their production systems.

Conclusion

From industrial aluminum to special materials, from precision breakthroughs to process innovation, PONC has written a legendary chapter in China's profile machining field with its and professionalism. Guided by the "Made in China 2025" initiative and the manufacturing strategy, PONC will continue to deepen its expertise in profile machining, drive industrial upgrading through technological innovation, contribute its professional strength to enhancing the core competitiveness of China's manufacturing industry, and continue to shine the light of Chinese on the global stage of profile machining.