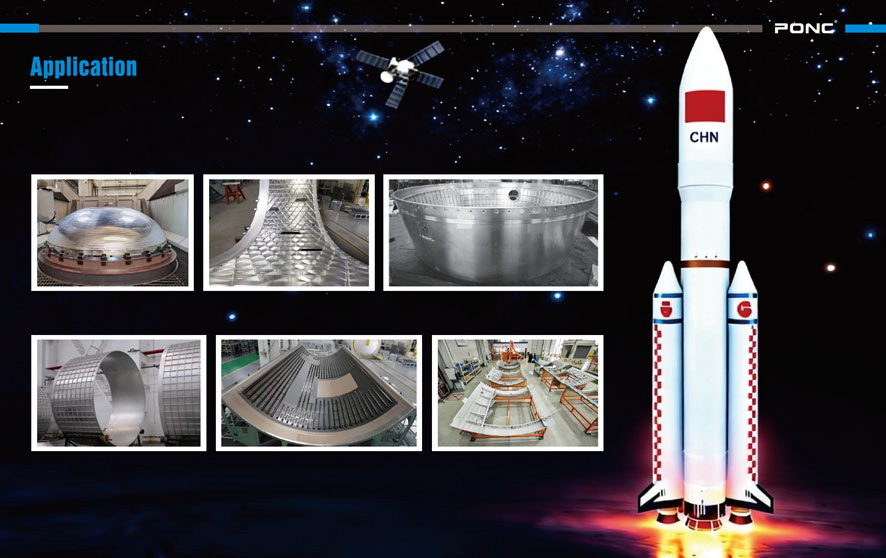

Five-axis gantry applied in aerospace/rocket manufacturing

January 05, 2026

In the field of commercial aerospace, a silent manufacturing revolution is underway. As SpaceX's reusable rockets pierce the sky and Blue Origin's suborbital vehicles land smoothly, these feats are supported not only by cutting-edge aerospace technology but also by precise manufacturing processes behind the scenes. In this revolution, the PONC PHC5D Five-Axis Gantry Machining Center, with its exceptional surface machining capabilities, has become an indispensable "mini-giant of surface machining" in the commercial aerospace supply chain.

Manufacturing Challenges and Opportunities in Commercial Aerospace

The rapid development of the commercial aerospace industry has brought unprecedented manufacturing demands. Compared with traditional aerospace, commercial aerospace companies face stricter cost-control pressures, faster iteration requirements, and more complex structural designs. Key components such as rocket engine nozzles, fuel tanks, fairings, and attitude control parts often feature complex curved geometric structures, posing extreme demands on material removal efficiency, machining accuracy, and surface quality.

In this context, five-axis gantry machining centers have become critical equipment for solving commercial aerospace manufacturing challenges. The PONC PHC5D, with its unique technical advantages, demonstrates exceptional adaptability in this field.

PONC PHC5D: Analysis of Technical Advantages

The PONC PHC5D Five-Axis Gantry Machining Center is designed for high-precision, complex surface machining, with technical features perfectly aligned with commercial aerospace manufacturing needs:

High Dynamic Precision and Stability: The PHC5D employs a thermally symmetric structural design and advanced thermal error compensation technology, ensuring micron-level precision during long-term continuous machining. This is crucial for aerospace components requiring extremely high reliability.

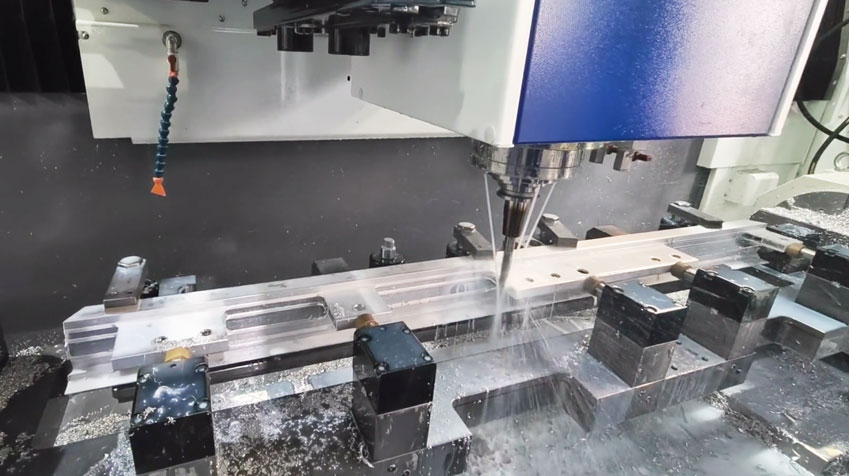

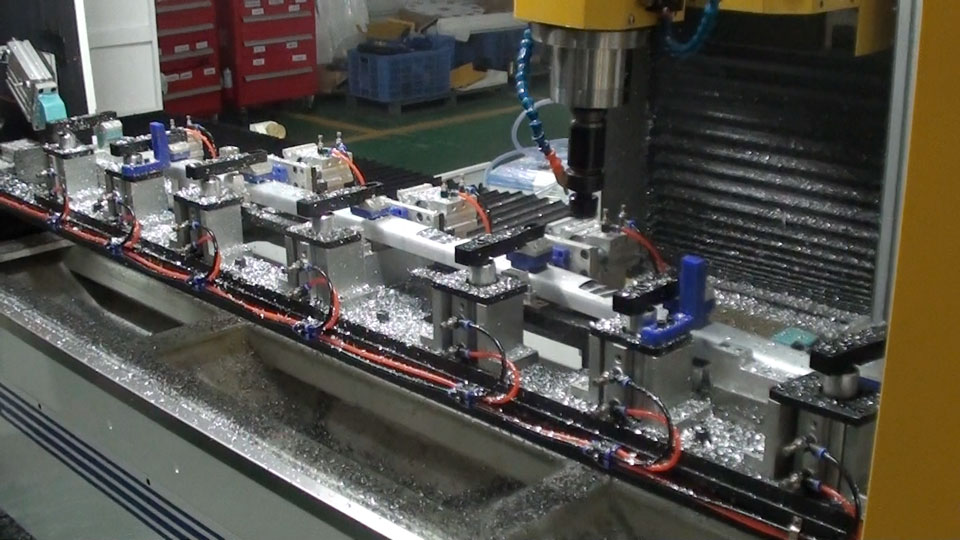

Five-Axis Simultaneous Machining Capability: The equipment is equipped with a high-performance dual-swivel milling head, enabling true five-axis simultaneous machining. It can complete precision machining of complex surfaces in a single setup, significantly reducing workpiece repositioning and greatly improving machining efficiency and accuracy.

Large-Scale Machining Space: The gantry structure provides an expansive machining area capable of accommodating large components in commercial rockets, such as fairing segments and fuel tank bodies.

Intelligent Control System: Integrated with smart functions like adaptive machining, vibration suppression, and collision detection, ensuring stability when machining thin-walled, difficult-to-process materials.

Application Practices in the Commercial Aerospace Field

1. Rocket Engine Component Machining

Combustion chambers, nozzles, and other components of commercial rocket engines are typically made of high-strength, high-temperature alloys or composite materials, featuring extremely complex internal cooling channels and curved structures. The PHC5D can precisely machine these complex surfaces, ensuring dimensional accuracy and surface quality of cooling channels, directly impacting engine thrust and thermal efficiency.

2. Lightweight Structure Manufacturing

To improve the payload ratio, commercial rockets widely adopt lightweight designs. The PHC5D can efficiently machine large thin-walled structural parts, such as fuel tank wall panels and interstage sections, maximizing weight reduction while ensuring structural strength.

3. Reusable Component Refurbishment

As reusable rockets become mainstream in commercial aerospace, inspection and repair of returned components pose new challenges. The PHC5D, equipped with a high-precision probing system, can perform 3D scanning on returned rocket parts, compare them with design models, and automatically generate refurbishment machining paths, significantly reducing reuse costs.

4. Satellite Structural Component Machining

Beyond rockets, commercial aerospace includes satellite manufacturing. The PHC5D can precisely machine precision components such as satellite brackets and antenna reflectors. Its high precision and stability ensure reliable operation of components in extreme space environments.

Industry Impact and Future Outlook

The application of the PONC PHC5D in commercial aerospace not only improves the manufacturing precision and efficiency of critical components but also drives innovation in design concepts. Engineers can now design more complex curved structures, knowing that reliable machining methods can realize these designs.

As commercial aerospace moves toward larger scale, higher frequency, and lower cost, the demand for advanced manufacturing equipment will become more urgent. In the future, hybrid machining centers integrating additive and subtractive manufacturing, along with intelligent machining systems with more powerful AI optimization capabilities, will set new industry benchmarks.

As a "mini-giant of surface machining," PONC has already established a significant position in the commercial aerospace manufacturing field. Its PHC5D Five-Axis Gantry Machining Center is not just a tool but a key enabler turning commercial aerospace dreams into reality, helping humanity explore and utilize space resources in more economical and efficient ways.

In the journey to the stars of commercial aerospace, it is these precise and reliable manufacturing tools that transform innovative designs into real spacecraft, launching humanity's space dreams time and again, and ushering in a new era for the aerospace industry.