Application of Profile Machining Centers in Cutting-edge Industries

December 15, 2025

As a vital branch of modern high-end CNC machine tools, profile machining centers are playing an indispensable role in the field of advanced manufacturing, thanks to their high precision, high automation, and high flexibility. By integrating multiple processes such as milling, drilling, and tapping on metal or composite material profiles, they enable the complete machining of complex structural components in a single setup, significantly enhancing manufacturing efficiency and accuracy. This article delves into the critical applications and core value of profile machining centers within four key frontier industries: the automotive industry, aerospace, solid-state batteries, and the low-altitude economy.

I. Automotive Industry: A Precision Pillar Amidst Lightweighting and Electrification

In automotive manufacturing, particularly with the rapid development of new energy vehicles (NEVs), the application of profile machining centers focuses on two core demands: lightweighting and structural integration.

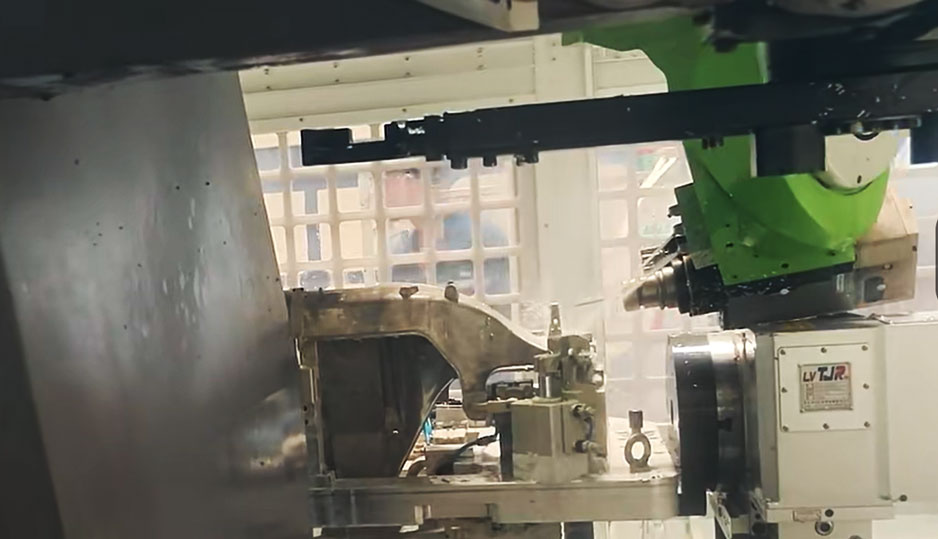

Chassis and Body Structural Components: Key safety parts such as aluminum alloy subframes, battery pack carrier frames, and body anti-intrusion beams have extremely high requirements for precision and strength. Profile machining centers can perform 3D precision machining on extruded aluminum alloy profiles, ensuring the accuracy of mounting holes and connection surfaces, thereby balancing weight reduction with safety. Localized high-precision machining is still crucial for body components, a stage where profile machining centers are essential.

Personalized and High-End Components: In high-performance or luxury vehicles, components like suspension links or instrument panel frames made from aluminum alloy or carbon fiber profiles rely on five-axis profile machining centers to achieve their complex aerodynamic or aesthetic surface machining.

Their value lies in supporting the automotive industry's pursuit of low-cost, high-efficiency, and high-quality production by improving material utilization, reducing workpiece handling, and ensuring batch consistency.

II. Aerospace Industry: Guardian of Extreme Performance and Reliability

The aerospace sector imposes near-stringent demands on part performance, reliability, and weight reduction. The application of profile machining centers here exemplifies cutting-edge manufacturing capability.

Aircraft Structural Components: Aircraft components like stringers, ribs, and longerons extensively use high-strength aluminum or titanium alloy profiles. These parts often feature complex contours, tight tolerances (often within ±0.05mm), and employ integrated designs to minimize fasteners. High-performance five-axis profile machining centers can handle difficult-to-machine materials like titanium alloys, achieving precision milling for thin walls, deep pockets, and multi-angle features, maximizing weight reduction while ensuring ultimate strength and fatigue life.

New Material Applications: With the increasing use of carbon fiber reinforced polymer (CFRP) profiles in wings and empennages, profile machining centers equipped with specialized tooling and dust extraction systems enable high-quality cutting, hole-making, and contour profiling of composite components, preventing delamination and burrs.

In this field, profile machining centers are not just tools but fundamental process enablers for achieving aircraft safety, economy, and advanced performance.

III. Solid-State Battery Industry: A Manufacturing Tool for the Next-Generation Energy Core

Solid-state batteries, as the most promising next-generation battery technology, have manufacturing processes significantly different from traditional lithium-ion batteries, posing new demands for precision manufacturing. Profile machining centers are primarily applied in two emerging areas:

Precision Machining of Battery Packs and Housings: To enhance energy density and safety, solid-state battery pack structures tend to be more compact and integrated. Their aluminum alloy or composite material housings require high-precision machining of surfaces, interfaces, and cooling channels. Profile machining centers ensure perfect fit for sealing surfaces and precise alignment with thermal management component interfaces, which is crucial for the safety, lifespan, and thermal management efficiency of the battery system.

Although this industry is still in its early industrialization stage, profile machining centers are already providing crucial precision manufacturing capability reserves for its transition from lab to mass production.

IV. Low-Altitude Economy Industry: A Key Driver for Aircraft Lightweighting and Mass Production

The low-altitude economy, centered around electric vertical take-off and landing (eVTOL) aircraft, drones, and other vehicles, is experiencing explosive growth. This poses the dual challenge of "automotive-grade" costs and "aerospace-grade" performance for aviation manufacturing. Profile machining centers serve as a bridging technology.

eVTOL Airframe Structures and Powertrain Components: To achieve high payload ratios, eVTOLs widely employ truss-type airframe structures made from aluminum alloy, titanium alloy, or even composites. These primary load-bearing frames and cabin skeletons, constructed from profiles with special shapes and numerous connection points, require precision machining by highly flexible machining centers to achieve lightweighting and high strength. Furthermore, complex linkages in tiltrotor mechanisms and motor mounting brackets also rely on multi-axis machining to ensure their kinematic accuracy and reliability.

High-Performance Drone Airframes: Industrial drones, designed for long endurance and high payload missions, often use monocoque airframes machined from carbon fiber or aluminum alloy profiles to reduce part count and improve structural efficiency. Profile machining centers enable rapid customized production of different airframe models.

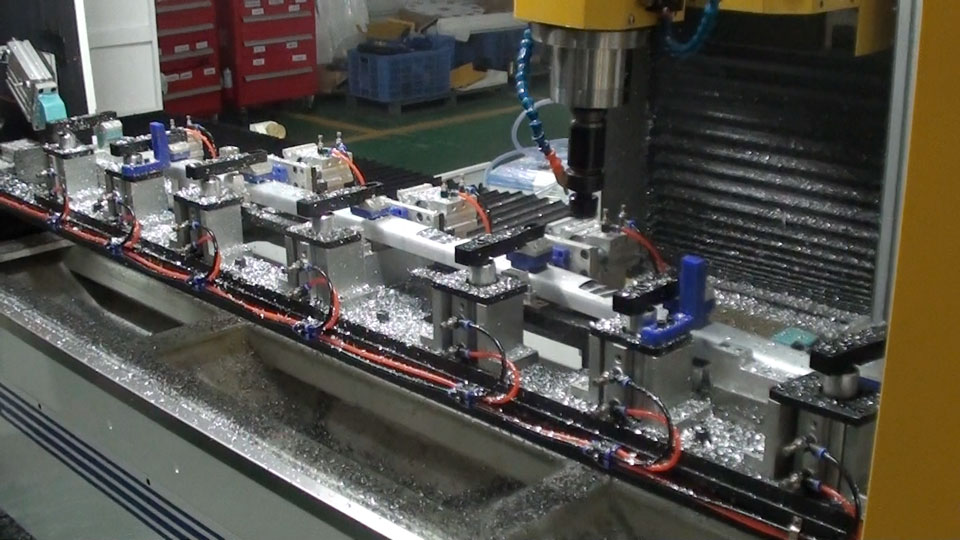

Adapting to Mass Production: For future large-scale manufacturing, profile machining centers, through automated loading/unloading, standardized fixtures, and intelligent programming, can provide stable, efficient, and reproducible component supply for low-altitude aircraft. This is key to reducing manufacturing costs and accelerating their commercialization.

Conclusion and Outlook

From speeding cars and soaring aircraft to revolutionary energy storage batteries and soon-to-take-flight vehicles, profile machining centers, with their exceptional precision machining and flexible production capabilities, deeply penetrate and empower the manufacturing core of these four frontier industries. Their value evolution is clear: from enhancing efficiency and precision (automotive) to challenging performance and reliability limits (aerospace), and further to shaping the manufacturing paradigms of emerging products (solid-state batteries, low-altitude economy).

Looking ahead, with the adoption of new materials (e.g., magnesium alloys, continuous fiber-reinforced thermoplastic composites), further product integration (e.g., multi-functional integrated vehicle bodies, Cell-to-Body/Chassis battery integration), and deepening digital transformation (digital twins, adaptive machining), profile machining centers will continue evolving towards higher precision, greater intelligence, higher levels of integration, and greener environmental profiles. They are not merely "executors" of high-end manufacturing but are evolving into "manufacturing hubs" that integrate design data, process knowledge, and intelligent decision-making, continuously providing a solid equipment foundation for the innovative development of modern industry.

NEXT: Differences in Machining Aluminum Profiles vs. Steel Profiles

PREV: End