Differences in Machining Aluminum Profiles vs. Steel Profiles

December 09, 2025

Many customers ask: "I need to process steel—can your profile machining centers handle it? Aren't they designed for processing aluminum?" In fact, whether machining aluminum or steel on a profile machining center, there is no fundamental difference in the milling process itself. What affects machining are primarily processing parameters and efficiency. We know that different series of aluminum materials (such as 6-series and 7-series aluminum) have varying hardness levels. The same applies to steel materials (such as Q235 carbon steel, 45# steel, and S136 mold steel).

Today, let’s discuss the differences from a machining process perspective:

Cutting Parameters and Efficiency

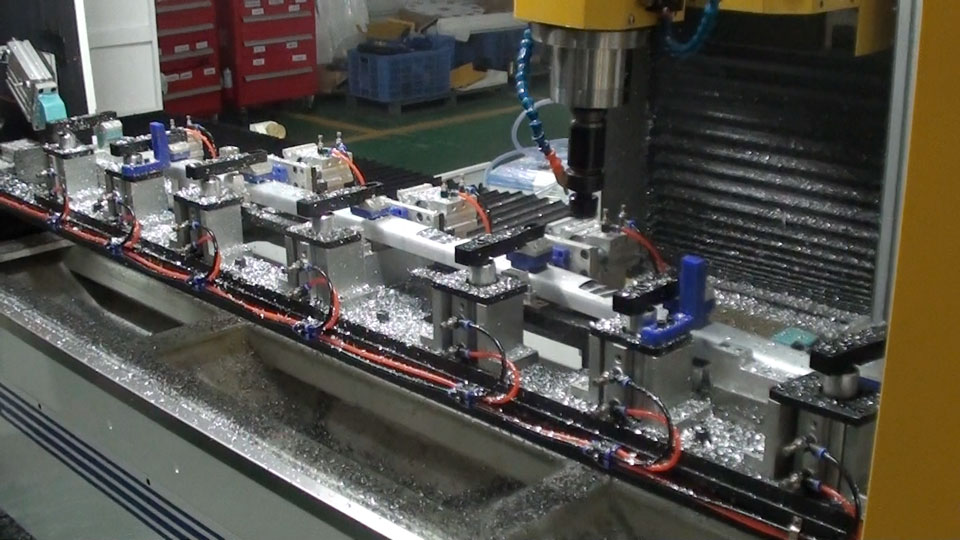

Aluminum machining: Typically involves high-speed cutting, utilizing high spindle speeds and high feed rates. Under the condition of sufficient machine rigidity, large cutting depths and feed rates are employed to achieve efficient material removal. Aluminum machining prioritizes high processing efficiency.

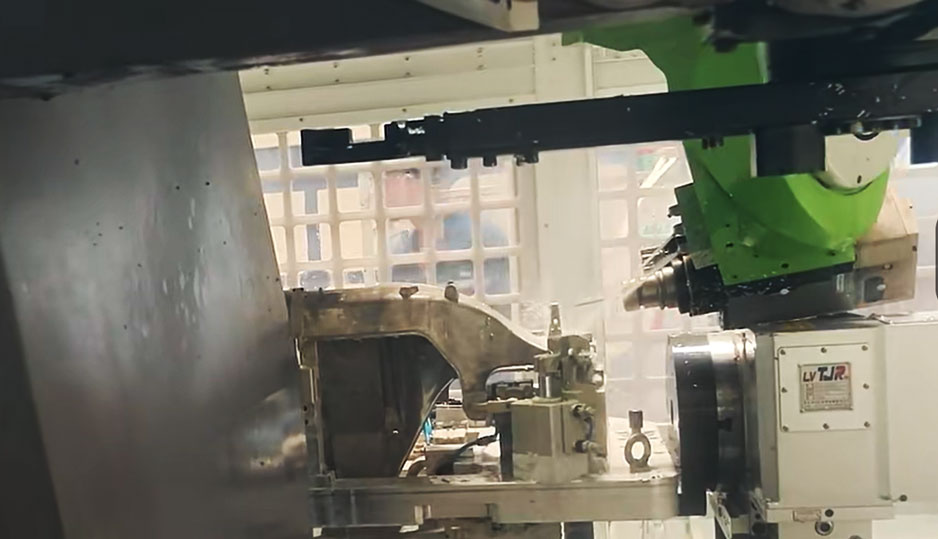

Steel machining: Requires relatively lower spindle speeds and feed rates. Due to limitations in cutting force and tool endurance, cutting parameters should be more conservative. The focus is on balancing efficiency while ensuring tool life and machining accuracy.

Tool Selection

Aluminum machining: Depending on the hardness of the material, tools with specific characteristics are selected, typically featuring large rake angles, large clearance angles, and large chip evacuation grooves to reduce chip adhesion.

Steel machining: Depending on the hardness of the material, tools with specific characteristics are selected, typically featuring smaller rake angles and stronger edge strength to withstand greater cutting forces and heat. Tools must be more wear-resistant and heat-resistant.

Cooling and Lubrication

Aluminum machining: Can be performed dry or with coolant (air blast or liquid cooling). The primary goal is chip evacuation rather than cooling.

Steel machining: Requires ample coolant to cool the tool and reduce workpiece temperature, preventing thermal wear and thermal deformation. Lubrication is also essential to reduce friction and cutting forces.

Machine Rigidity

Rigidity is relative in machining. For both aluminum and steel, insufficient machine rigidity can lead to vibration or chatter during cutting. Adjusting or reducing certain parameter values can help mitigate this issue.

Therefore, for profile machining centers, processing both aluminum and steel is feasible. The primary consideration is long-term machining efficiency. It’s important to choose equipment that better suits your specific processing needs based on the types of products you work with. Currently, there are many types of profile machining centers tailored to different industries, such as new energy vehicles, module manufacturing, roller shaft production, and aerospace. The configurations may also vary depending on the materials being processed. Contact us to recommend the equipment that best suits your needs.