Why Aluminum Profile Processing Centers Have Become the Market Mainstream

January 23, 2026

This is a very core and professional question. The fact that profile machining centers (especially those for aluminum profiles) have become mainstream equipment is no coincidence; it is the result of the combined effect of market demand, material properties, and equipment advantages.

We can understand this in depth from the following levels:

1. Macro-Market Drivers: Why "Aluminum"?

The huge market demand for aluminum profiles themselves is the root cause driving the need for specialized machining centers.

Core Material for Lightweighting Trends:

New Energy Vehicles: Battery pack casings, body structures, motor mounts, etc., extensively use aluminum alloys to reduce weight and increase range. These components require high-precision drilling, tapping, and milling.

Aerospace: Aluminum and its alloys are the main materials for aircraft structures like frames and skins, requiring extremely high machining accuracy and efficiency.

Rail Transit: High-speed rail and subway car bodies also widely use large aluminum profiles, necessitating specialized machining equipment.

Green Building and Doors/Windows/Curtain Walls:

Aluminum alloy doors, windows, curtain walls, and sunrooms are standard in the construction industry. These profiles require cutting, grooving, and drilling for assembly, involving massive processing volumes.

Industrial Automation and Robotics:

Aluminum profiles (like t-slot extrusions) are the "building blocks" for automated production lines, equipment guards, robot fences, and workbenacles. Their connection points require extensive end-face machining and hole processing.

Consumer Electronics and Heat Dissipation Components:

Phone frames, laptop casings, LED heat sinks, etc., heavily use aluminum alloys, requiring high surface finish and precision CNC machining.

2. Machining Characteristics of Aluminum: Why is it Suitable for "Machining Centers"?

The physical and chemical properties of aluminum make it an "ideal workpiece" for machining centers.

Excellent Machinability:

Compared to steel, titanium alloys, etc., aluminum alloys have lower hardness and smaller cutting forces, resulting in slower tool wear and enabling high-speed cutting. This perfectly matches the high-speed, high-feed characteristics of machining centers.

Superior Thermal Conductivity:

Heat generated during machining is quickly carried away by the chips and the workpiece, preventing deformation due to localized overheating and protecting the tool. This enables long-term, efficient continuous processing.

Relatively Low Cost:

Raw material costs are lower than copper, magnesium alloys, etc., and machining loss costs are also lower, making large-scale production economically feasible.

3. Technical Advantages of Profile Machining Centers: Why "Them"?

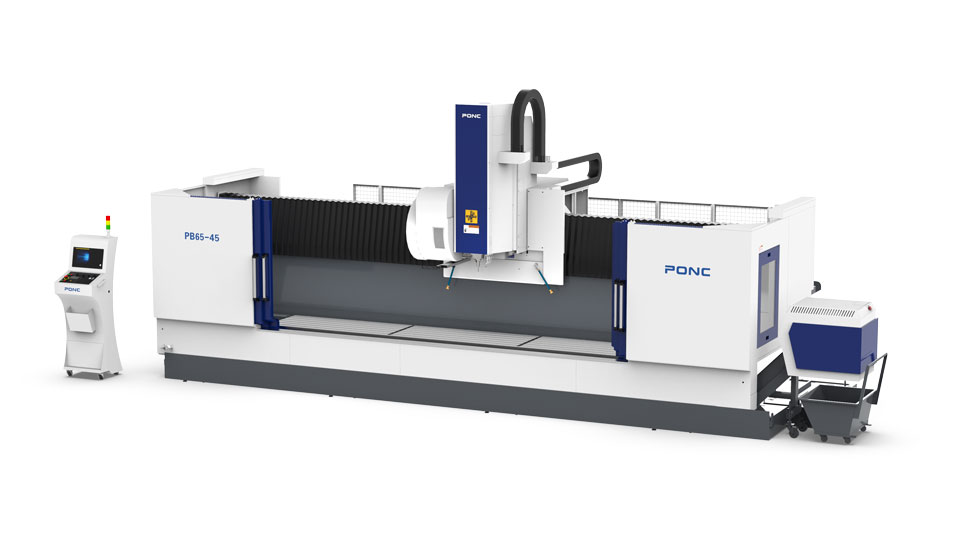

To meet the machining needs of aluminum profiles, profile machining centers have been specifically optimized, far surpassing general-purpose equipment in efficiency, accuracy, and automation.

High Production Efficiency:

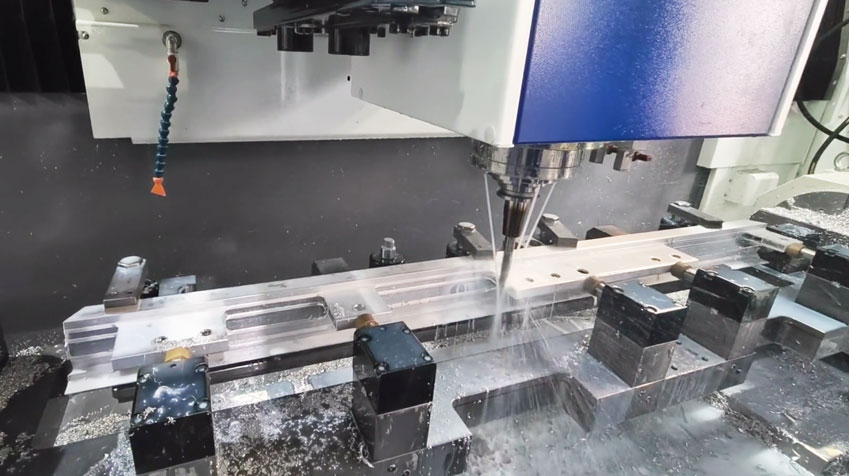

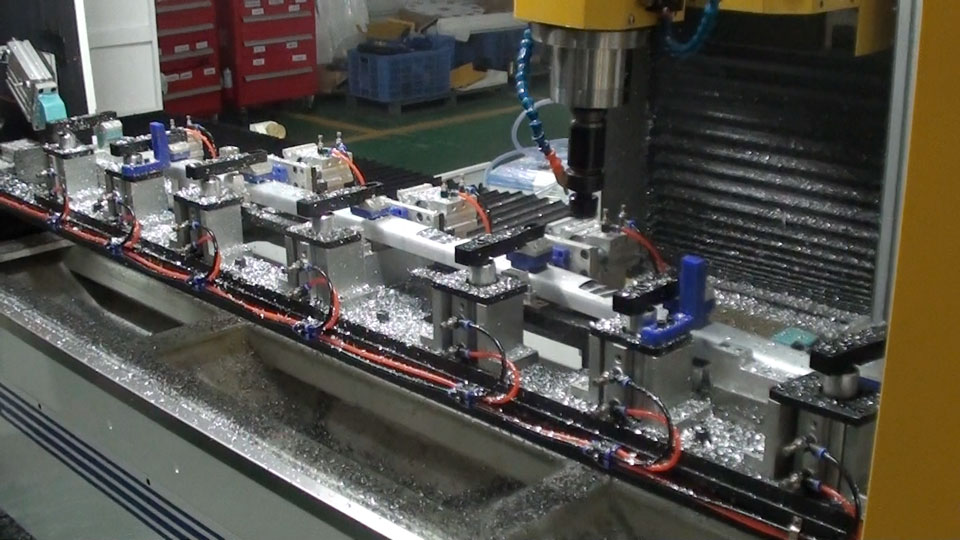

Multi-Spindle Design: Common configurations with three, four, or even six spindles can machine multiple profiles or multiple sides simultaneously, multiplying efficiency.

Efficient Chip Removal System: Designed to handle the long, stringy chips typical of aluminum, equipped with powerful high-flow coolant systems and screw conveyor chip removal, ensuring a clean working area and continuous production.

Integrated "Machine-Measure-Compensate": High-end models integrate on-line measurement probes that can automatically detect hole position dimensions and perform tool compensation, reducing downtime and ensuring high yield rates.

Superior Machining Accuracy and Consistency:

Specialized Fixturing and Bed Structure: Designed for long profiles with multi-segment positioning fixtures and a rigid bed structure, effectively suppressing vibration and deformation during machining, ensuring accuracy along the entire length.

CNC System: Fully controlled by CNC programs, eliminating human operational errors. Regardless of batch size, every part remains consistent.

Strong Flexible Manufacturing Capability:

"Quick-Change" Systems: By rapidly changing fixtures and calling different machining programs, they can quickly switch between profiles of different specifications and processing requirements. This perfectly adapts to today's trend of "high-mix, low-volume" customized production.

Automation and Smart Integration:

Profile machining centers are easily integrated into automated production lines. They can be connected to automatic loaders, robots, AGVs, etc., achieving fully automated, unmanned production from raw material to finished product – something traditional milling and drilling machines cannot match.