Application of Profile Machining Centers in the Solid-State Battery Industry

October 23, 2025

In the pursuit of higher energy density and ultimate safety in the new energy industry, solid-state batteries are hailed as the "Holy Grail" of next-generation power batteries. However, transitioning from laboratory breakthroughs to mass production presents a series of daunting engineering challenges. In this disruptive industrial transformation, a seemingly traditional yet crucial equipment—the profile machining center—is playing an indispensable role as the "unsung hero," clearing obstacles and laying the foundation for the industrialization of solid-state batteries.

Structural Characteristics and Manufacturing Challenges of Solid-State Batteries

Unlike traditional liquid lithium-ion batteries, solid-state batteries employ solid electrolytes, resulting in a more compact and precise structure. This brings several core manufacturing requirements:

Extremely High Sealing Requirements: To prevent air (especially moisture) from infiltrating and causing failure of the solid electrolyte and electrode materials, the battery casing must possess near-perfect airtightness.

Complex Internal Cavities and Flow Channels: To ensure uniform heating and effective heat dissipation during operation, the battery casing often requires precisely designed thermal management channels.

Application of New Materials: To meet demands for lightweighting, high strength, and special compatibility, casings may use aluminum alloys, stainless steel, or even more specialized metal materials.

Dimensional Accuracy and Consistency: In mass production, every battery pack frame and component must maintain micron-level precision to ensure smooth automated assembly and the final product's reliability.

These stringent requirements pose unprecedented challenges for the equipment responsible for machining battery packs, module frames, and key structural components.

Profile Machining Centers: Why Are They the "Chosen One"?

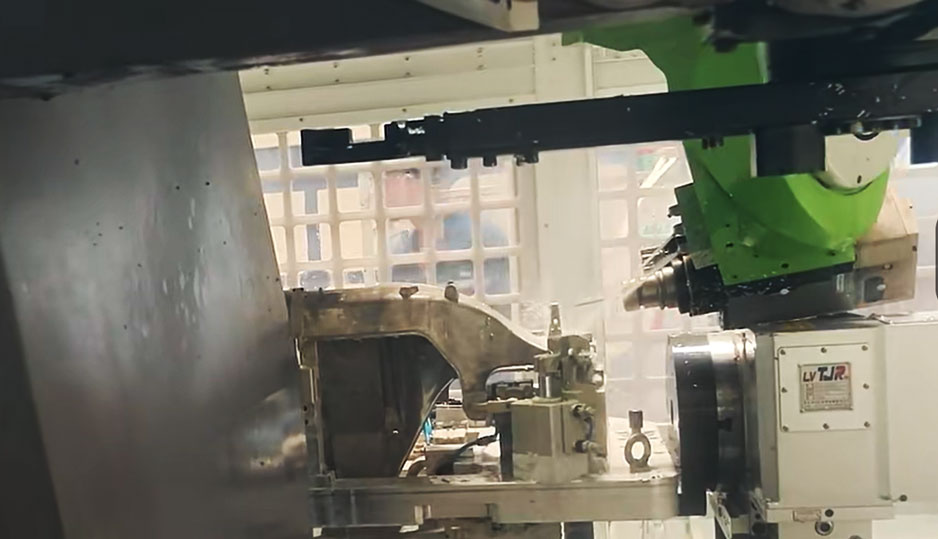

A profile machining center is a high-end CNC machine tool specifically designed for processing long metal profiles (such as aluminum or steel profiles). Its suitability as an ideal choice for solid-state battery manufacturing stems from the following core advantages:

Achieving "High Precision" and "Zero Leakage": Sealing is the lifeline of solid-state batteries. Profile machining centers, through multi-axis linkage, rigid bed structures, and advanced CNC systems, can complete the precision machining of all key features of the battery casing—such as end faces, sealing grooves, and filling ports (if applicable)—in a single setup. They can achieve surface finishes of Ra 1.6 or better and guarantee geometric tolerances like flatness and perpendicularity, providing a perfect base surface for installing laser-welded covers or special sealing rings, eliminating leakage risks at the source.

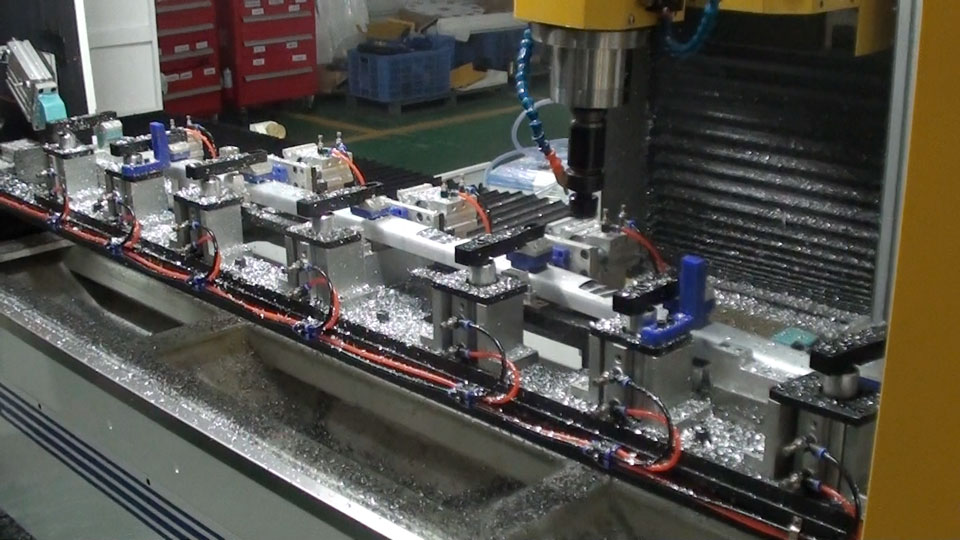

Excelling at Complex Machining of "Deep Cavities and Narrow Grooves": The thermal management flow channels in solid-state batteries are often deeply embedded within the casing, featuring complex structures. Profile machining centers are typically equipped with long-reach tools, internal coolant systems, and high-speed electric spindles, enabling efficient deep-hole drilling and cavity milling. Whether for winding coolant channels or small hole systems for sensor placement, they handle the tasks with ease, ensuring the battery's thermal stability during fast charging and high loads.

Ensuring Efficiency and Consistency in "Mass Production": The industrialization of solid-state batteries inevitably involves large-scale, automated production. Profile machining centers are designed with features like automatic feeding, multi-station synchronous machining, and in-process measurement. A production line can continuously and automatically process meters-long profiles, which are then automatically cut into individual battery frames by robots. This "complete machining in a single setup" model significantly improves production efficiency and ensures impeccable consistency across thousands of products, something manual operation or ordinary machine tools cannot match.

Meeting the Machining Needs of "Diverse Materials": To address the different metal materials potentially used in solid-state batteries, profile machining centers can flexibly adapt by changing tools and adjusting cutting parameters (speed, feed rate). Whether machining lightweight, gummy aluminum alloys or higher-strength stainless steels, they can find the optimal machining strategy to ensure quality and extend tool life.

Application Scenarios: From the "Skeleton" to the "Skin"

Profile machining centers are ubiquitous in the solid-state battery production chain:

Battery Pack Frames and Cross Beams: Machining various aluminum profiles that form the main structure of the battery pack, including mounting holes and connection slots.

Individual Battery Housings: Precision machining of the metal housings for each solid-state battery cell, including sealing surfaces, terminal through-holes, and internal cavities.

Thermal Management System Components: Machining substrates for liquid cooling plates or vapor chambers with integrated cooling channels.

End Plates and Side Plates: Manufacturing reinforced structural components used to secure cell modules.

It can be said that the precision and quality of everything from the "skeleton" supporting the entire battery pack to the "protective skin" encasing each cell are directly determined by the performance of the profile machining center.

Future Outlook: Evolving with Solid-State Batteries

As solid-state battery technology continues to mature, the requirements for their structural components will only increase. Future profile machining centers will inevitably evolve towards greater intelligence and integration:

Intelligence and Adaptability: Integrating more sensors and AI algorithms to enable real-time monitoring of the machining process, automatic tool wear compensation, and fault prediction, moving towards "unmanned dark factories."

Process Integration: Integrating subsequent processes such as cleaning, deburring, and inspection into the machining center itself, achieving "machining-complete" and further improving overall efficiency.

Higher Flexibility: Enabling rapid switching of machining programs to adapt to the fast iteration and small-batch, multi-variety trial production needs of solid-state battery products.

The dawn of solid-state batteries is visible, but the path to their widespread adoption still needs to be paved diligently. As representatives of high-end manufacturing equipment, profile machining centers, with their exceptional precision machining capabilities, stable mass production performance, and strong material adaptability, are quietly building the sturdy and reliable "physical载体" for solid-state batteries. They may not directly participate in the revolution of electrochemical reactions, but they are undoubtedly the most solid backbone of this revolution. When the first mass-produced solid-state battery rolls off the line, it will undoubtedly embody the wisdom and craftsmanship originating from the profile machining center.