Profile Processing Center: Revolutionizing Efficiency and Cost-Effectiveness for Extra-Long Workpieces, Effortlessly Handling 26-Meter High-Speed Rail Components

October 28, 2025

In the grand tapestry of modern manufacturing, high-speed rail undoubtedly stands out as a dazzling pearl. Behind it lie countless precision-manufactured components, many of which are incredibly long profile structural parts, such as the car body's underframe, side rails, and roof panels, often reaching lengths of over 20 meters, even 26 meters. How to efficiently, precisely, and economically process these "steel giants" has always been a challenge in the manufacturing industry. Traditionally, gantry machining centers might come to mind first, but a more specialized and targeted equipment – the machining center for profiles – is establishing itself as the king in the realm of ultra-long workpiece processing with its exceptional performance.

I. Challenges: Pain Points in Ultra-Long Workpiece Machining

Machining a 26-meter-long aluminum alloy or stainless steel profile is no easy task. Traditional solutions face numerous bottlenecks:

1. Equipment Limitations: The door width and travel of ordinary gantry machining centers are limited. Custom-building an ultra-large gantry with a 26-meter span is extremely costly and requires a massive footprint.

2. Low Efficiency: The workpiece requires multiple clamping and repositioning cycles, leading to significant cumulative errors and long machining cycle times, severely impacting production efficiency.

3. Difficulty Maintaining Precision: Long workpieces are prone to deformation and vibration under their own weight and cutting forces. Multiple clamping is a major killer of accuracy.

4. Labor-Intensive: Requires multiple operators to coordinate hoisting and positioning, resulting in low automation levels and high labor intensity.

II. Solution: The Superior Design of Machining Centers for Profiles

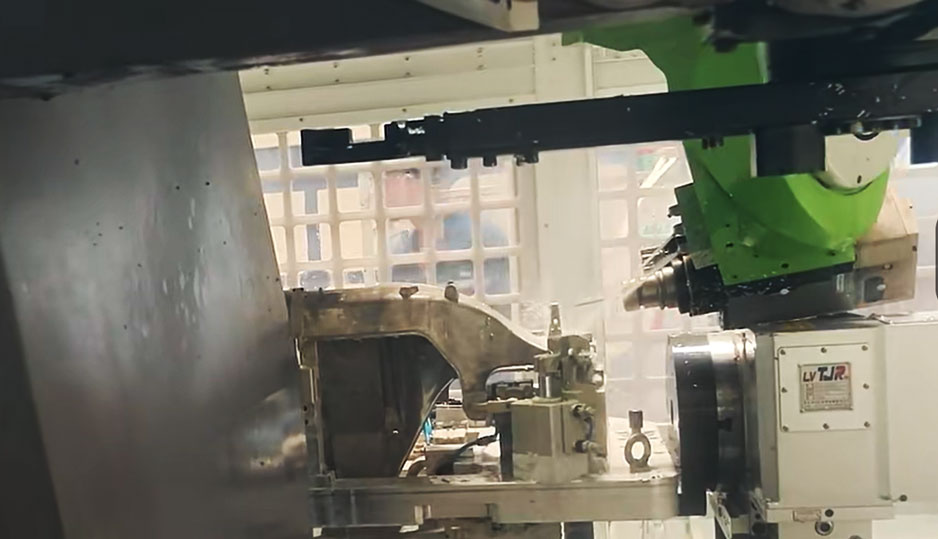

Machining centers for profiles, especially moving-column or gantry-type 5-sided machining centers designed specifically for ultra-long workpieces, provide a perfect solution to the aforementioned pain points. Their core design philosophy is "the machine moves, the workpiece remains stationary."

• Ultra-Long Travel & Fixed Workpiece: The workpiece is fixed in place once on an extra-long work table, remaining stationary. The machining spindle, driven by a rigid structure comprising the bed, column, and beam, moves along the entire length (e.g., 26 meters) of the workpiece to perform machining.

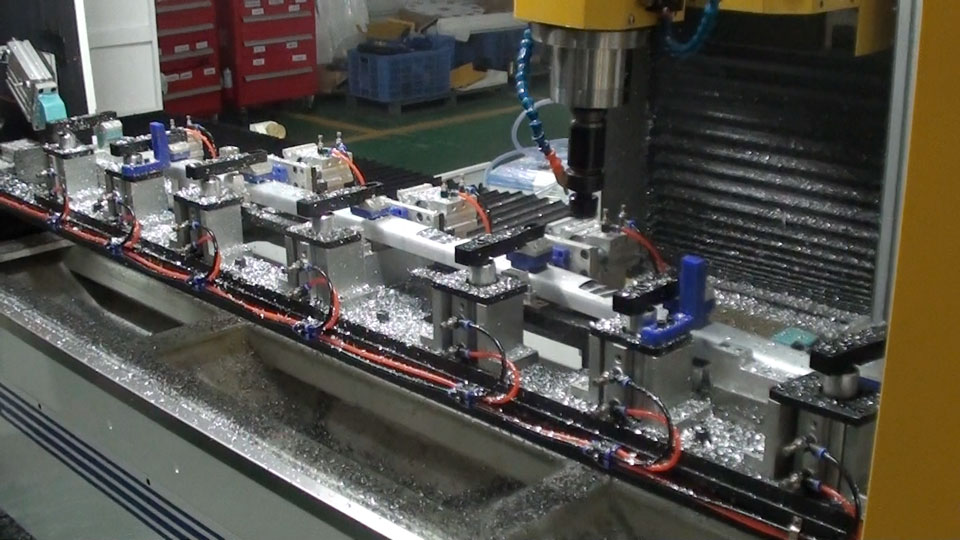

• Professional Clamping System: Equipped with multiple adjustable hydraulic or pneumatic clamps distributed evenly along the work table, effectively supporting the long workpiece and preventing deformation and vibration during machining.

• Multi-Spindle Heads & Tool Magazine: Typically equipped with efficient automatic tool changers, and sometimes multiple spindles working simultaneously, capable of completing various processes like milling, drilling, tapping, and boring in a single setup, achieving "complete in one clamp."

III. Core Advantages: Why Faster, More Economical, and Better Value than Gantry Machining?

Compared to custom-built ultra-large gantries for specific projects, machining centers for profiles offer comprehensive advantages when processing ultra-long profiles.

1. Efficiency Leap: A Revolution in Speed

• Reduced Non-Cutting Time: The most significant efficiency gain comes from single setup. A 26-meter workpiece might require moving and re-alignment 2-3 times on a gantry machine, each taking hours. The profile machining center requires only one clamping, saving vast amounts of auxiliary time.

• Multi-Tasking Parallel Processing: High-end profile machining centers can be equipped with dual spindles or multiple work tables. While one spindle is machining, another area can handle workpiece loading/unloading, enabling near-continuous production and far higher equipment utilization than ordinary gantries.

• High-Speed & High Dynamic Performance: The structure optimized for profile machining means the moving parts (spindle) have relatively less mass compared to moving the entire gantry, allowing for higher feed rates and accelerations, shortening the cycle time for individual operations like hole making.

2. Significant Economical Benefits: Cost Optimization

• Lower Initial Investment: The design and manufacturing costs for a custom-built giant gantry with 26 meters of effective travel grow exponentially. Standard series profile machining centers, extending travel through modular design, often offer a more advantageous overall cost for equivalent machining lengths.

• Smaller Footprint: The layout of profile machining centers is more compact, not requiring extra space for the large movement range of a gantry frame, saving valuable factory floor area.

• Reduced Labor & Energy Costs: High automation levels and power concentration on spindle movement (compared to driving the entire massive gantry structure) lead to lower energy consumption over long-term operation.

3. King of Value: Perfect Combination of Precision and Flexibility

• Higher Precision Stability: The "single setup" principle fundamentally eliminates cumulative errors from multiple repositioning. Coupled with precise bed guides and linear scales, it easily ensures high-precision machining over the full 26-meter length. The fixed workpiece also facilitates better chip removal and coolant application, avoiding accuracy impacts from thermal deformation.

• Excellent Flexibility: One profile machining center can adapt to various profile workpieces with different cross-sections and lengths. Quick changeover for production is achieved simply by changing fixture programs and tools, making it ideal for the high-mix, low-volume production model common in high-speed rail. A custom giant gantry appears "cumbersome" in comparison.

• Reliability & Maintenance: The structure is relatively simpler than traditional gantries, with more rational force distribution on moving parts, leading to higher long-term operational stability and reliability, and easier daily maintenance.

IV. Specific Application in High-Speed Rail Manufacturing

Taking the example of machining a 26-meter-long aluminum alloy profile for a high-speed rail car body underframe:

1. Loading: The profile blank is placed onto the work table clamps via overhead crane or automatic conveyor.

2. Single Setup & Positioning: The operator starts the program; all clamps automatically tighten, securing the workpiece.

3. Automatic Machining: The program starts; the machining center spindle moves along the X-axis (length direction), coordinated with Y/Z axis movement, performing sequentially on various faces of the profile:

o Milling mounting surfaces

o Drilling hundreds of connection holes

o Tapping

o Milling grooves and contours

4. Completion & Unloading: After all operations are complete, the clamps release, the finished workpiece is hoisted away, the next blank enters, and the cycle begins.

The entire process is smooth and efficient, akin to a precise "industrial sewing machine" skillfully working on its custom-made "fabric."

The machining center for profiles, by its very nature designed for long workpiece processing, indeed surpasses the scope of traditional gantry machining centers in terms of efficiency, economy, and overall value for money, making it the unequivocal choice for such applications. It represents not merely a simple extension of machining capability but embodies an advanced manufacturing philosophy of "using specialization to conquer length, using movement to control stillness." It is a key propelling high-end equipment manufacturing to a higher level.