Profile Machining Center: A Versatile and In-Depth Flexible Manufacturing Platform.

November 24, 2025

Traditionally, we have been accustomed to categorizing machine tools based on processing size into "vertical machining centers" and "gantry machining centers." However, the emergence and evolution of profile machining centers precisely break this boundary. To define it accurately, we need to adopt a more three-dimensional and comprehensive perspective.

I. Core Definition: The "Length"-Based, Dynamically Covering Processing Expert

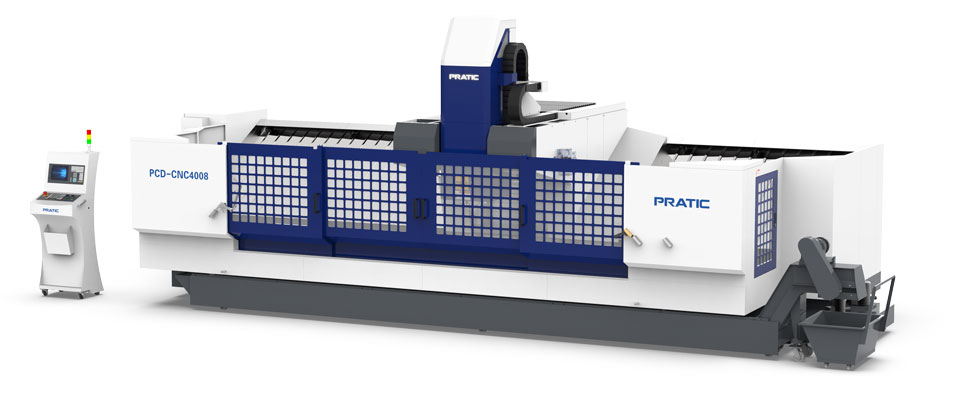

A profile machining center is a multi-functional CNC machining center based on a "moving column" structure, specifically designed for efficiently processing long workpieces (especially profiles). It leverages its unique structural rigidity and flexibility to cover the processing range of both large gantry machines and small vertical machines.

In essence, it is not a single-function dedicated device, but rather a flexible manufacturing platform with powerful length adaptability.

II. Analysis of Core Characteristics

Extreme Elasticity in Processing Length: Coverage from "Meters" to "Millimeters"

This is the most prominent advantage of the profile machining center. Its design初衷 is to handle long profiles measuring several meters or even over ten meters, which inherently grants it an exceptionally long X-axis travel.

• Competence in "Long" Workpieces: When facing several-meter-long aluminum or steel profiles, it operates like a "mobile processing line," completing all processes from start to finish. This ensures the overall machining accuracy and consistency of long workpieces, which is unattainable by ordinary vertical machining centers (VMCs).

• Compatibility with "Short" Workpieces: Precisely because of its super-long worktable and travel, it can easily accommodate multiple small workpieces. Using dedicated or modular fixtures, dozens or even hundreds of small parts (such as metal connecting blocks, small brackets) can be clamped simultaneously on its huge worktable for one-time, batch processing. This means that when processing small parts, the output efficiency per clamping of a single profile machining center far exceeds that of ordinary VMCs.Signature "Fixed Table" Machine Structure

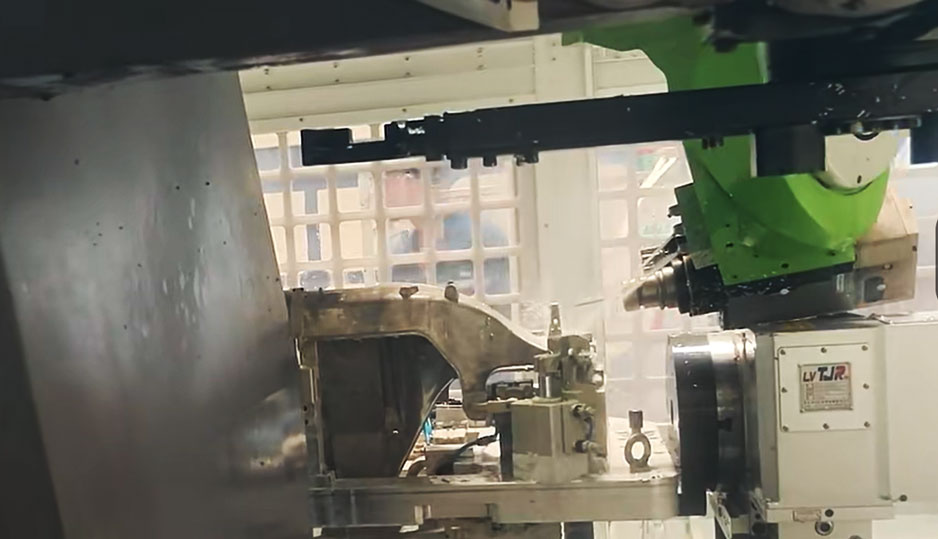

Profile machining centers almost exclusively adopt a moving column structure. The worktable is completely fixed, bearing and clamping the workpiece; while the spindle head moves in the X, Y, and Z directions on a sturdy gantry or column frame structure. This significantly reduces the equipment's footprint. This structure brings decisive advantages:

• Unparalleled Stability: No matter how long or heavy the workpiece, it is firmly locked onto the bed, eliminating inertia, vibration, and accuracy loss caused by table movement. This is the fundamental guarantee for achieving high-precision machining of long workpieces.

• Excellent Load Capacity: The fixed table can be designed to be extremely robust, easily carrying long workpieces weighing several tons.

• Machining Consistency: The stationary workpiece means the machining datum remains unchanged. Regardless of where the spindle moves on the table, the machining mechanical environment is consistent, ensuring stable machining quality from start to finish.Cross-Border Machining Capability: The Convergence of Gantry and VMC Functions

Based on the above two points, the profile machining center becomes a unique "cross-border" machine.

• It can replace some tasks of gantry machining centers: For many products primarily structured with long profiles (such as high-speed rail car bodies, large cabinet frames, curtain wall keels), the profile machining center is fully capable. It can perform all milling, drilling, tapping, cutting, and other processes on these long workpieces, with efficiency even higher than traditional gantries designed for heavier, larger box-type parts.

• It can replace the work of multiple vertical machining centers: When dealing with large batches of small parts, its massive fixed worktable transforms into an "integrated machining cell." Through multi-station fixture layout, it achieves one-time programming and continuous processing. Its output per unit time far exceeds that of a single VMC requiring frequent material changes and tool setting, showing huge efficiency and economic advantages in mass production.

Therefore, a profile machining center cannot be simply viewed as an "elongated VMC" or a "scaled-down gantry." Its precise definition is:

A composite, high-efficiency CNC manufacturing platform centered around a fixed worktable and moving column structure, specializing in machining long profiles, and seamlessly covering processing from large long workpieces to batches of small parts through its structural rigidity and workspace advantages.

It represents an optimal solution born from the dual pursuit of "flexibility" and "efficiency" in modern manufacturing, finding a perfect balance between specialization and versatility, making it a sharp tool for achieving smart manufacturing and lean production.