Profile Machining Centers: Technologies and Future Trends

August 11, 2025

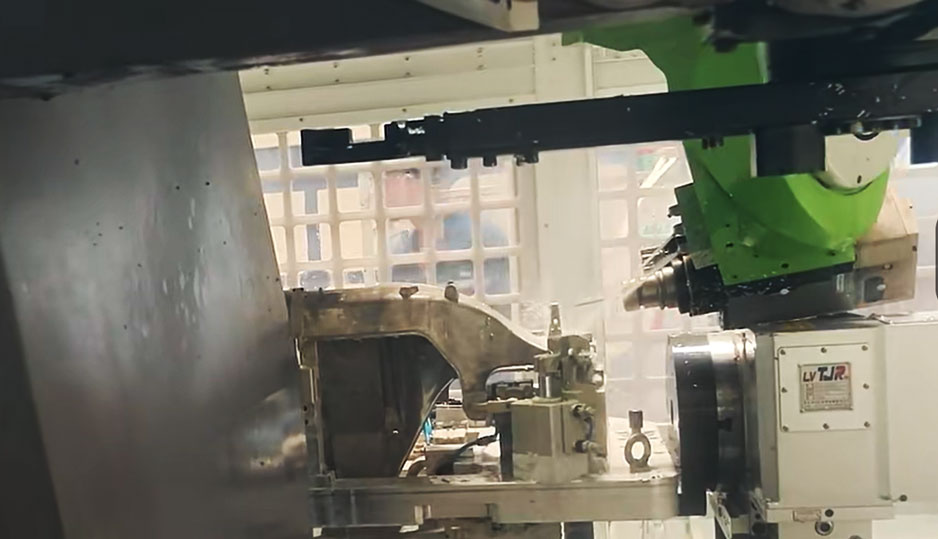

1. Overview and Industry Positioning of

Profile Machining Centers

As an important branch of the CNC machine

tool field, profile machining centers are specialized

integrated equipment designed for efficient and precise machining of metal

profiles (such as aluminum profiles, steel profiles, etc.). Compared with

traditional universal machining centers, profile machining centers feature

longer machining strokes, stronger structural rigidity, and more specialized

machining capabilities, meeting the high-efficiency processing demands for

large, complex profile components in industries such as rail transportation,

aerospace, and automotive manufacturing.

Profile machining centers are gradually evolving from single-purpose machining equipment

to intelligent manufacturing units. By integrating automated loading/unloading

systems, online inspection devices, and intelligent management systems,

modern profile machining centers have become a critical

component of digital factories, providing key technical support for

manufacturing enterprises to enhance quality and efficiency.

2. Core Technical Features of Profile

Machining Centers

1. Specialized Structural Design

Modern profile machining centers employ

various innovative structural forms:

- Gantry-moving structure: Suitable

for extra-long profile machining, saving floor space.

- Dual-worktable design: Enables

parallel processing and loading/unloading operations, improving equipment

utilization.

- High-rigidity bed: Constructed from

high-quality cast iron or welded steel with reinforced rib designs to

ensure machining stability.

2. Multi-functional Machining

Capabilities

A modern profile machining center can

integrate multiple machining functions:

- Milling: Surface milling, contour

milling, cavity milling, etc.

- Hole machining: Drilling, reaming,

boring, etc.

- Thread machining: Tapping, thread

milling, etc.

- Cutting: Sawing, milling, and other

profile cutting functions.

3. Intelligent Control Systems

- High-performance CNC systems supporting five-axis simultaneous

machining.

- Equipped with adaptive control systems to adjust parameters in

real-time based on machining conditions.

- Integrated remote monitoring for visual management of equipment

status and predictive maintenance.

3. Main Application Fields of Profile

Machining Centers

1. Rail Transportation Industry

- Machining of large aluminum profile frames for high-speed

rail/subway carriages.

- Precision machining of structural components such as roof beams

and sidewall columns.

- Machining of bogie components with accuracy requirements within

±0.01mm.

2. Aerospace Sector

- Machining of aircraft skins, wing spars, and other aviation

aluminum materials.

- High-precision milling of spacecraft structural components.

- Special machining of difficult-to-machine materials like

titanium alloys.

3. Automotive Manufacturing

- Machining of battery trays for new energy vehicles.

- Integrated forming and machining of vehicle body structural

components.

- Machining of parts such as bumpers and instrument panel

brackets.

4. Architectural Decoration Industry

- Precision machining of curtain wall aluminum profiles.

- Milling and hole-cutting for door/window system profiles.

- Complex shaping of decorative trim components.

4. Key Considerations for Selecting

Profile Machining Centers

When purchasing a profile machining

center, enterprises should focus on the following factors:

- Workpiece characteristics:

Including material, cross-sectional dimensions, length range, etc.

- Accuracy requirements: Select the

appropriate precision grade based on product tolerance needs.

- Production efficiency: Evaluate

metrics such as cutting efficiency and tool-changing time.

- Automation level: Assess the need

for additional functions like automatic loading/unloading or online

measurement.

- Scalability: Consider future

technical upgrades and functional expansions.

5. Development Trends in Profile

Machining Technology

1. Toward Higher Efficiency

- Spindle speeds exceeding 20,000 rpm.

- Rapid traverse speeds reaching 60 m/min or higher.

- Tool-changing times reduced to under 1 second.

2. Toward Greater Intelligence

- Big data-based optimization of machining parameters.

- Automatic tool wear detection and compensation.

- Online prediction and adjustment of machining quality.

- Intelligent monitoring and management of energy consumption.

3. Toward Greater Flexibility

- Modular designs enabling quick changeovers.

- Rapid response to small-batch, multi-variety production.

With the continuous emergence of new

materials and processes, profile machining centers are

undergoing profound technological transformations. In the future, profile

machining technology will advance toward higher precision, greater efficiency,

and enhanced intelligence, providing robust equipment support for the

transformation and upgrading of the manufacturing industry.

For manufacturing enterprises, selecting the right profile machining center and fully leveraging its performance advantages will become a critical pathway to enhancing core competitiveness. It is recommended that enterprises consider future development trends during equipment selection and process planning, opting for technologically forward-looking solutions to lay a solid foundation for long-term growth.