Profiling Machining Centers Drive Intelligent Transformation in Auto Parts Manufacturing

July 28, 2025

In the tide of modern manufacturing pursuing high precision, high efficiency, and high automation, the PONC PB65-25 Profile Machining Center, with its outstanding performance, is becoming the equipment of choice for numerous industry-leading enterprises. Especially in the automotive parts manufacturing sector, its stable and reliable machining capability provides a solid foundation for building automated production lines.

Outstanding Performance: The Core Competitiveness of the PONC PB65-25 Profile Machining Center

High-Rigidity Bed Structure: Utilizes high-quality cast iron and an optimized rib design, employing large-inclination integrated casting. This ensures rigidity while optimizing the chip removal system, providing fundamental assurance for large-chip-volume machining and automated line production.

Higher Efficiency: Equipped with a powerful spindle motor, offering rapid traverse speeds of 50m/min and acceleration of 0.7G – enabling a direct takeoff into high-speed machining. It delivers ample cutting torque, easily handling the efficient machining of common automotive materials like aluminum alloys and steel.

At a well-known automotive parts manufacturing base in Anhui, the PONC PB65-25 Profile Machining Center demonstrated its formidable production capabilities. This factory specializes in producing key structural components for new energy vehicles, demanding extremely high standards for machining efficiency, precision, and equipment stability.

Large-Scale Application: The factory introduced over thirty PONC PB65-25 Profile Machining Centers in one go, establishing multiple modern flexible automated production lines.

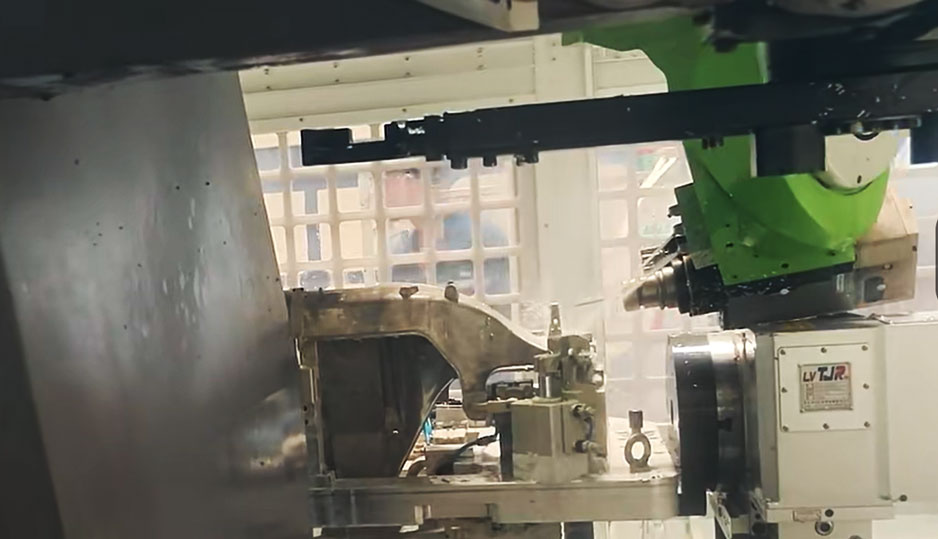

Core of Automation Integration: These PB65-25 centers serve as the core machining units within the production lines. They are seamlessly integrated via precision automation systems (such as gantry robots, articulated arm robots, or ground rails), working in concert with automatic material warehouses, in-line inspection stations, and other processes. This achieves fully unmanned or minimally manned operations encompassing the entire workflow from blank loading and precision machining to quality sampling and finished product unloading.

Productivity Leap: The automated lines operate continuously and stably 24/7. Compared to traditional stand-alone machines or semi-automatic modes, productivity has increased several-fold, powerfully ensuring the timely delivery of customer orders.

Stable and Reliable: The equipment's low failure rate and high reliability form the cornerstone for smooth automated line operation, while ease of maintenance reduces operational pressure. According to on-site feedback, the comprehensive equipment failure rate is below 1%, guaranteeing continuous and efficient production line operation.

The PONC PB65-25 Profile Machining Center, with its powerful performance, ultra-high precision, and stable, reliable core capabilities, perfectly meets the urgent demands of modern manufacturing—especially the automotive parts industry—for efficient, intelligent, and automated production. The successful implementation at the Anhui factory fully demonstrates that the PB65-25 is not just a single high-performance machine, but a crucial building block for constructing the intelligent factories of the future.

Choosing the PONC PB65-25 means choosing higher production efficiency, superior product quality, and stronger market competitiveness. It empowers enterprises to seize opportunities in intense market competition, advancing "Made in China" to "Intelligent Manufacturing in China".

Interested in learning how the PONC PB65-25 Profile Machining Center can boost your automated production line upgrade? Or want detailed solution examples similar to the Anhui factory case? Contact us anytime!