How to Select a Profile Machining Center and Why PONC Stands Out

August 27, 2025

In the field of industrial manufacturing, especially in the deep processing of metal materials such as aluminum profiles, stainless steel, and carbon steel, profile machining centers have become core equipment for improving production efficiency, ensuring machining accuracy, and achieving complex processes. Faced with a wide array of brands and models on the market, how to choose the most suitable profile machining center for one's needs has become a critical decision for many business leaders. This article will systematically outline the key selection points and ultimately reveal why PONC is a trustworthy and excellent choice.

I. Clarify Your Needs: The Foundation of Selection

Before making a choice, it is essential to conduct a clear self-analysis:

Processing Materials: Are you primarily processing aluminum profiles, iron materials, stainless steel, or composite materials? Different materials have varying hardness and toughness, which place different demands on the machine tool's rigidity, spindle power, and cutting speed.

Product Characteristics: The size (length, width, height) and weight of the workpiece determine the required travel (X, Y, Z axes) and load-bearing capacity of the equipment. Profile machining particularly focuses on processing length.

Process Requirements: Is there a need to perform multiple processes such as milling, drilling, tapping, boring, grooving, and cutting? This determines the required functional configurations, such as tool magazine capacity (whether automatic tool change is needed) and whether a fourth axis (rotary axis) is required for four-sided machining.

Production Capacity Goals: What is the expected daily/monthly output? This relates to the requirements for equipment efficiency and the degree of automation (e.g., loading machines, feeding machines).

Budget Range: Set a reasonable investment budget and balance the initial procurement cost with long-term usage and maintenance costs.

II. Examine Core Performance: The Key to Selection

After clarifying needs, strictly examine the core performance indicators of the equipment:

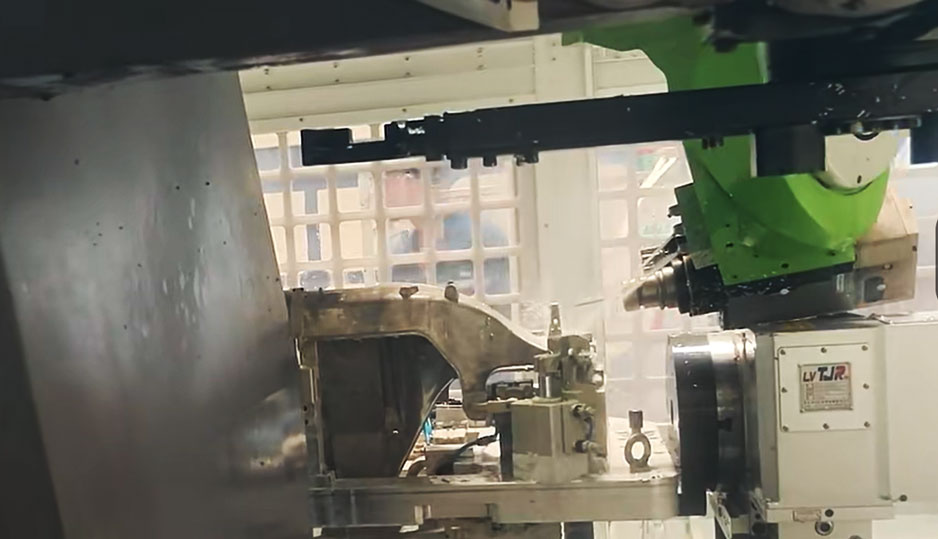

Machine Tool Structure and Rigidity: Are the bed, column, and other basic structural components made of high-quality cast iron or steel? Excellent materials and rational rib design are the foundation for ensuring long-term stability and machining accuracy of the machine tool, effectively resisting cutting vibrations.

Core Component Brands:

Spindle: As the "heart," its power, torque, speed range, and brand (e.g., Taiwanese, Japanese, German brands) are crucial and directly determine cutting capability.

CNC System: As the "brain," mainstream systems like Fanuc, Siemens, and Mitsubishi offer high stability, user-friendly operation, and a rich ecosystem.

Ball Screws and Guides: High-precision ball screws and linear guides (preferably linear rails) are key to ensuring motion accuracy and lifespan.

Accuracy and Stability: Pay attention to the equipment's positioning accuracy and repeatability. Understand how the manufacturer ensures the stability of these accuracies over long-term use through technology (e.g., pitch compensation, thermal compensation).

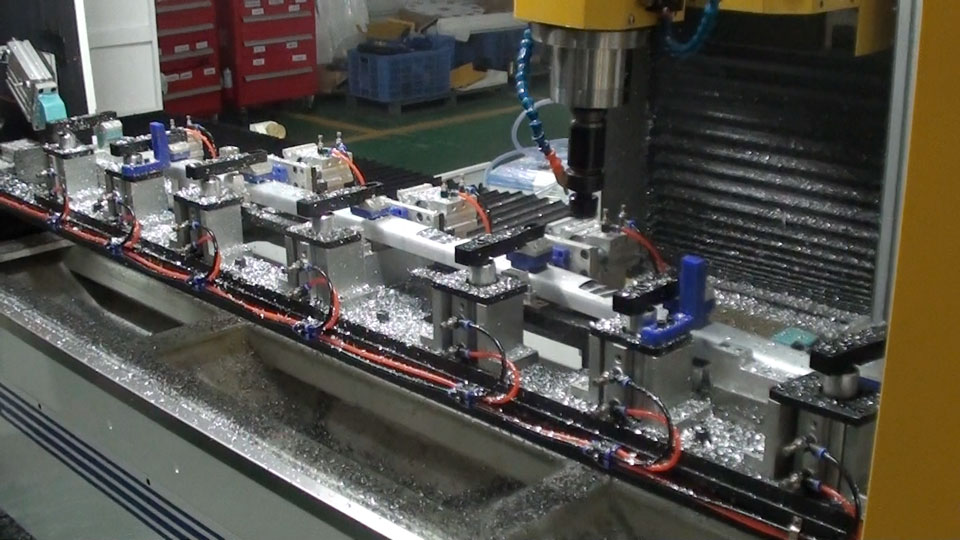

Automation and Flexibility: For profile machining, automatic feeding systems, efficient fixtures, and large-capacity tool magazines can significantly improve efficiency and reduce manual intervention. Is the equipment's programming software easy to learn and use? Can it quickly adapt to new product processing?

Safety and Protection: Does the equipment have comprehensive safety protection devices and alarm systems to ensure operator safety and stable equipment operation?

III. Evaluate Soft Power: The Added Value That Cannot Be Ignored

Beyond hardware, the brand's soft power equally determines long-term value:

Technical Support and After-Sales Service: Can the manufacturer provide rapid response, professional technical support, and reliable spare parts supply? A after-sales network can minimize downtime losses.

Technical Training: Does it provide comprehensive systematic training on operation, programming, and maintenance to help your team get up to speed quickly?

Industry Reputation and Case Studies: Investigate the brand's application cases and customer reputation in your industry. Feedback from real users is the most persuasive proof.

IV. The Final Choice: Why is PONC Your Ideal Partner?

After comprehensive consideration from all angles, PONC is undoubtedly a brand that fully meets all these stringent requirements. Its advantages shine brightly among numerous competitors:

Professional Focus, Deep Insight: PONC is not a "jack-of-all-trades" machine tool manufacturer but an expert long focused on the field of profile machining. It has a deep understanding of the unique process requirements for aluminum profiles and non-ferrous metal processing. Its products are tailored for profile machining from the initial design stage.

Excellent Performance, Reliable Stability: PONC machining centers use a high-rigidity bed structure and high-quality core components, ensuring powerful cutting capability and long-term accuracy stability. The excellent performance of its equipment when handling large, long-sized profile processing has won widespread market praise.

Efficient Automation, Empowering Production: PONC understands the principles of efficient production deeply and offers various automation solutions from automatic feeding and intelligent fixtures to multi-spindle linkage, which can significantly increase production capacity, reduce unit costs, and help customers gain a competitive edge.

Technological Leadership, Continuous Innovation: (PONC always insists on R&D investment), not only pursuing excellence in hardware but also continuously innovating in software systems and intelligent control, making equipment operation simpler, programming smarter, and machining more precise.

Service First, Full Escort: PONC has built a comprehensive technical support and after-sales service network, providing customers with full-lifecycle guarantees from pre-sales solution planning, mid-sales installation and commissioning, to post-sales rapid response and maintenance. This ensures customers can purchase with confidence and use without worry.

Choosing a profile machining center is a significant strategic investment. It should not merely be the purchase of a piece of cold equipment but the selection of a long-term partner to fight side by side. From clarifying your own needs, to scrutinizing core performance, and then to evaluating the brand's soft power, each step requires careful decision-making.

And when you follow this clear path to finally reach the decision point, PONC, with its profound professional (accumulation), proven product quality, efficient solutions, and trustworthy service commitment, perfectly meets all these expectations. Choosing PONC is not only choosing a high-performance machining equipment but also choosing a guarantee, an efficiency, and a powerful boost towards a higher level of manufacturing.

Investing in PONC is investing in your company's future productivity and competitiveness.