Fixed Beam Gantry VS Vertically Moving Beam Gantry

August 22, 2025

Core Differences at a Glance

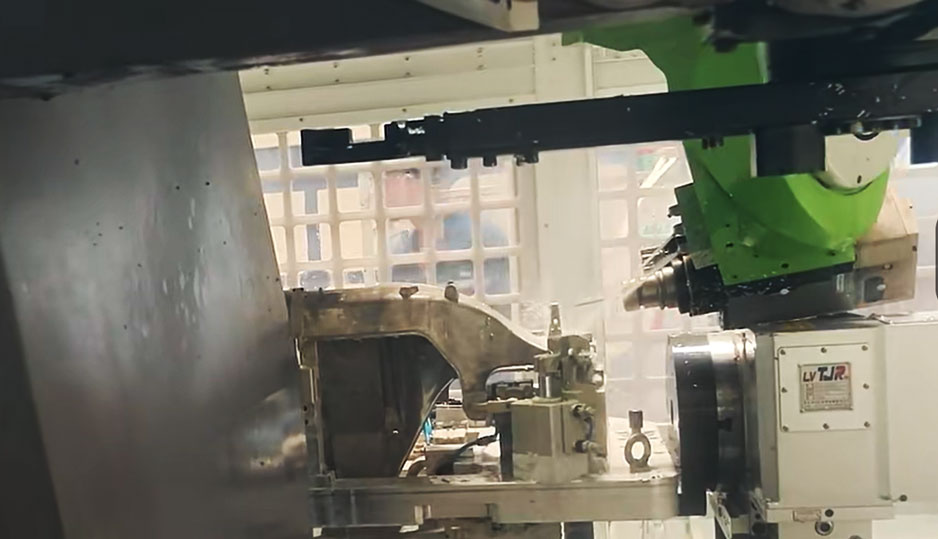

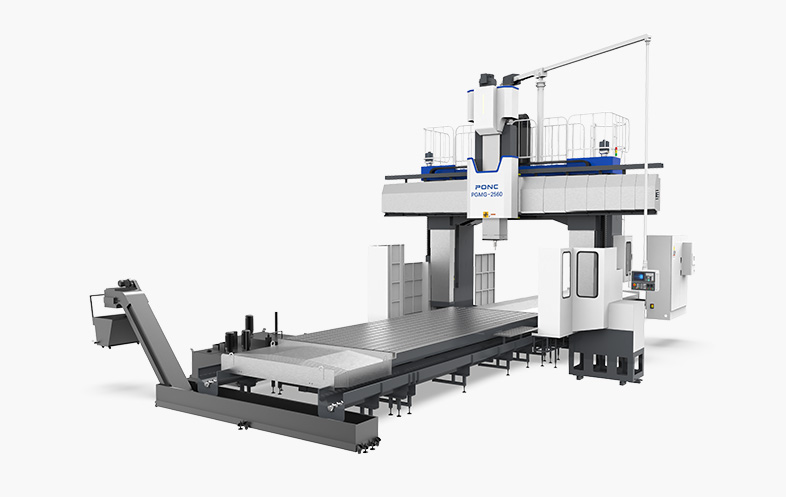

• Fixed Beam with Moving Table: The gantry's beam (X-axis) is fixed. During machining, the worktable moves with the workpiece along the base in the front-rear (Y-axis) direction. The spindle head moves left and right (X-axis) and up and down (Z-axis) along the beam.

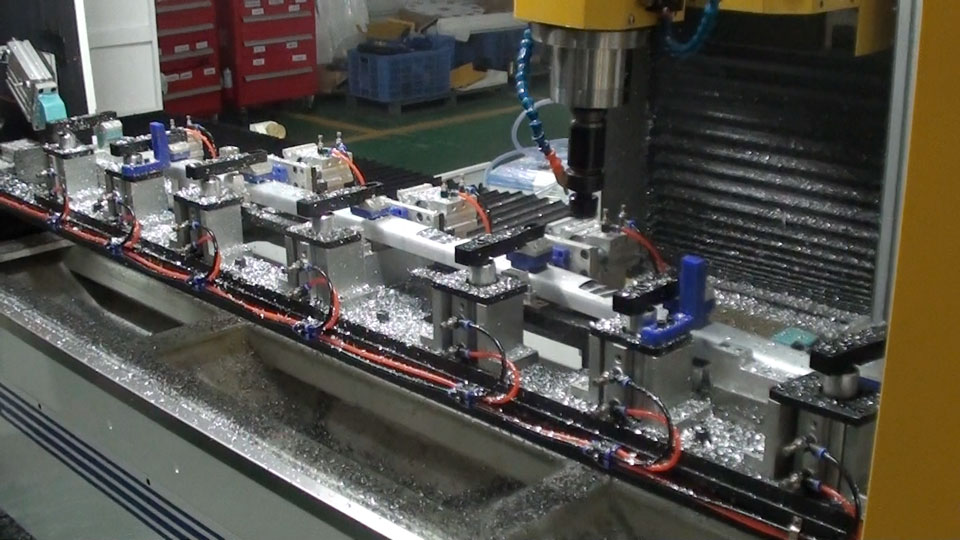

Fixed Beam Gantry

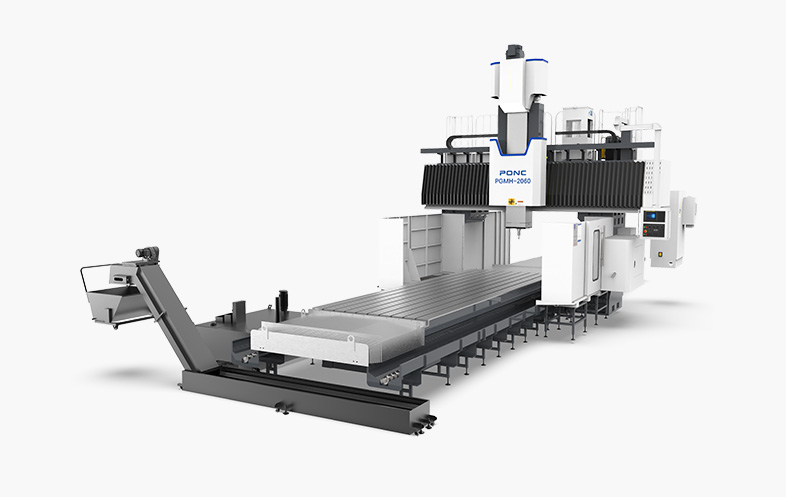

• VerticallyMoving Beam with Moving Table: The entire beam (X-axis) of the gantry can move up and down as a whole (Z-axis motion). During machining, the worktable still moves with the workpiece in the front-rear (Y-axis) direction, while the spindle head only moves left and right (X-axis) along the beam. The vertical lifting (Z-axis) is accomplished by the entire beam.

Detailed Comparative Analysis

Feature Dimension | Fixed Beam Gantry | Vertically Moving Beam Gantry |

Core Structure | The beam is fixed to the two columns and cannot move vertically. Z-axis motion is achieved by the spindle ram. | The beam and the two columns form an integrated structure, allowing the entire beam to move significantly along the column guides in the Z-direction. |

Motion Method | - X-axis: Spindle head moves along the beam | - X-axis: Spindle head moves along the beam |

Rigidity/Stability | Excellent. Since the beam is fixed, the structural rigidity of the entire gantry framework is very high, minimizing vibration and deformation. | Good. However, the beam lifting mechanism introduces additional connection points, theoretically making the overall rigidity slightly lower than that of a fixed beam structure of the same specifications. |

Machining Precision | Typically higher. High rigidity ensures excellent dynamic stability, maintaining higher precision, especially during heavy cutting. | Precision is also very good, but the lifting motion of the large beam component requires high control standards and may be slightly affected by factors such as thermal deformation. |

Load Capacity | Strong. The worktable directly carries the workpiece, typically offering high load capacity (ranging from several tons to hundreds of tons). | Very strong. The load capacity is equally impressive, and the movable beam makes it easier to hoist oversized and ultra-heavy workpieces. |

Pros and Cons | Pros: | Pros: |