Profile Machining Centers and Their Applications in the New Energy Vehicle Industry

August 15, 2025

I. What is a Profile Machining Center?

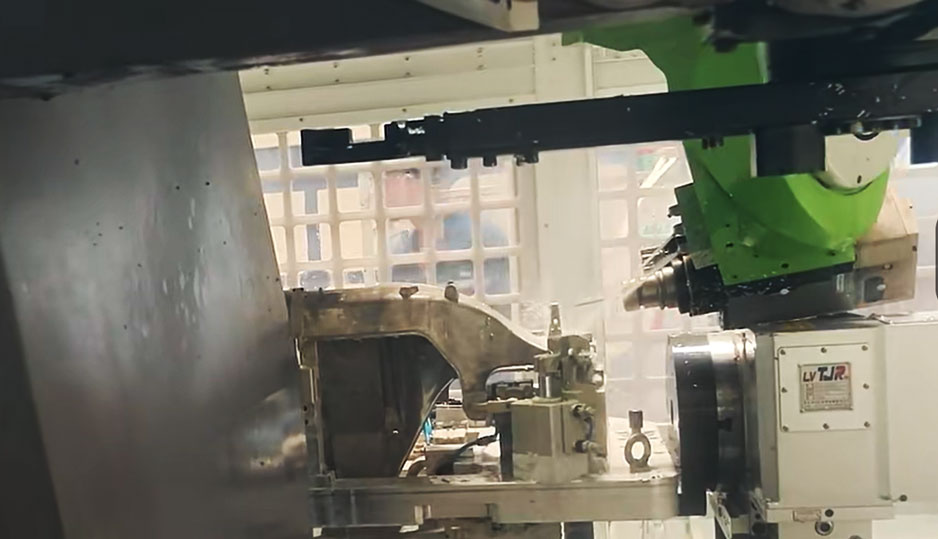

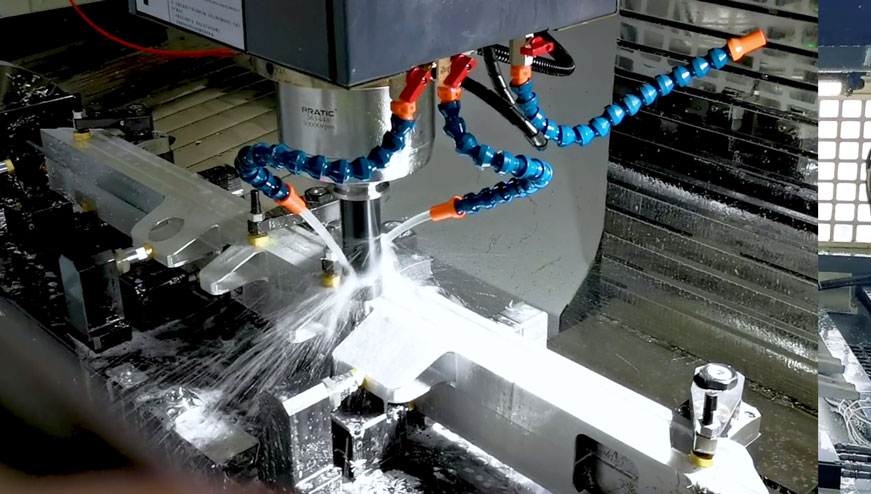

A profile machining center is a high-precision, long-travel CNC machine tool specifically designed for processing metal or non-metal profiles (such as aluminum alloys, steel, composite materials, etc.). It integrates multiple machining functions, including milling, drilling, tapping, cutting, chamfering, and more. Through multi-axis linkage and automated control, it enables efficient and precise machining of complex, long-length profiles.

Core Features of Profile Machining Centers:

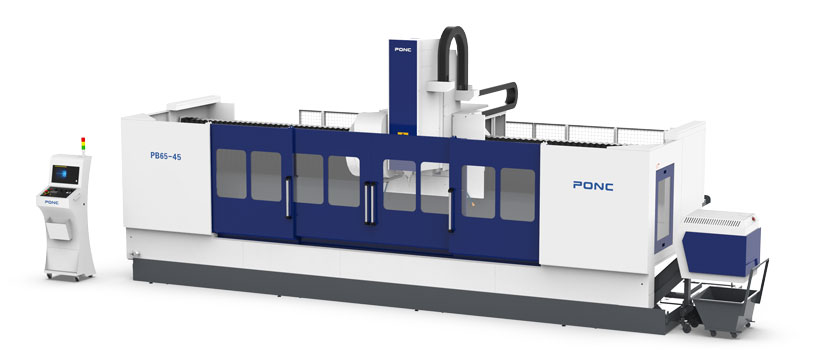

Extra-Long Travel: Exceeds the travel range of standard vertical machining centers, comparable to the X-axis travel of large gantry machining centers.

High Processing Efficiency: Lighter moving components than gantry machines, enabling faster rapid traverse speeds and higher overall machining efficiency.

Multi-Axis Linkage: Typically equipped with 3-axis, 4-axis, or 5-axis capabilities, allowing for the machining of complex curved surfaces and irregular structures.

High-Precision Machining: Utilizes a high-rigidity bed and precision servo systems to ensure machining accuracy of up to ±0.02mm or better.

High Automation: Compatible with automatic loading/unloading systems and robotic integration for unmanned production.

Multi-Function Integration: Multiple processes can be completed on a single machine, reducing workpiece clamping times and improving efficiency.

Specialized Fixture Design: Custom fixtures for different profiles (e.g., aluminum extrusions, tubes) ensure machining stability.

Profile machining centers are widely used in industries such as construction, rail transportation, aerospace, and automotive manufacturing, playing a particularly vital role in the new energy vehicle sector.

II. Applications of PONC Profile Machining Centers in the New Energy Vehicle Industry

The new energy vehicle industry's growing demand for lightweight, high-strength, and precision machining has led to the widespread use of materials like aluminum alloys and carbon fiber profiles. As a result, PONC profile machining centers have become key equipment in this field.

1. Machining Requirements for New Energy Vehicle Components

Core components of new energy vehicles include:

Battery Trays (Battery Housings) – Made of aluminum alloy profiles, requiring high-precision milling, drilling, and tapping.

Motor Housings – Demand high-rigidity machining to ensure sealing and heat dissipation.

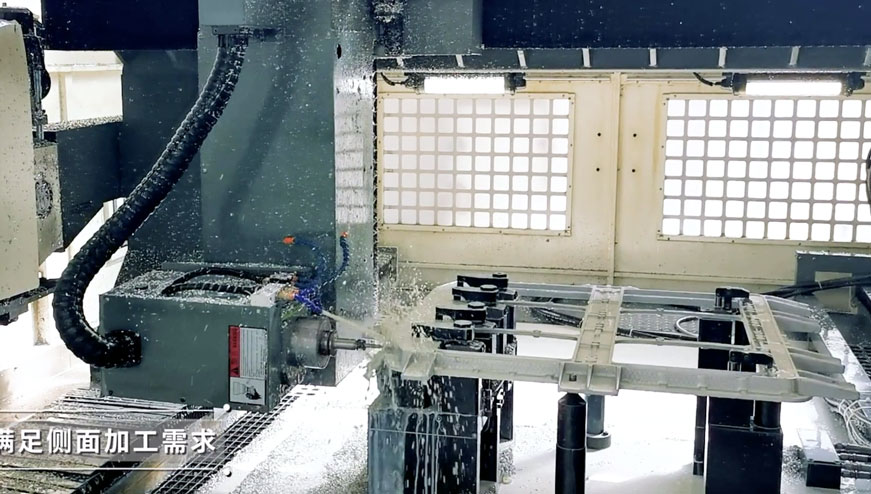

Body Structural Components (Crash Beams, Sill Beams, etc.) – Precision machining of lightweight aluminum profiles.

These components require extremely high machining accuracy, efficiency, and quality consistency. Traditional machining methods struggle to meet the demands of ultra-high-volume production, making PONC profile machining centers—with their high rigidity, precision, and efficiency—an ideal solution.

2. Advantages of PONC Profile Machining Centers

PONC, a leading domestic CNC machine tool manufacturer, offers profile machining centers with the following advantages in the new energy vehicle industry:

High Dynamic Response: Utilizes high-precision linear guides and servo motors to meet high-speed machining needs.

Modular Design: Customizable fixtures and tooling systems for different workpiece requirements.

Intelligent Automation: Supports robotic loading/unloading, reducing manual intervention and improving production efficiency.

Energy Efficiency & Environmental Friendliness: Optimized cutting parameters minimize material waste, aligning with the green manufacturing philosophy of new energy vehicles.

Profile machining centers are critical equipment in new energy vehicle manufacturing, and PONC’s machines—with their high precision, efficiency, and intelligent features—play a significant role in machining core components such as battery trays and body structural parts. In the future, as the new energy vehicle industry continues to grow, profile machining technology will further advance, providing even more efficient solutions for the sector.