The Outstanding Application of PONC Profile Machining Centers in the Automotive Industry

September 16, 2025

As the automotive industry strides toward electrification, lightweighting, and intelligence, innovation in manufacturing technology serves as the cornerstone supporting this transformation. Among these advancements, PONC profile machining centers, representing high-end CNC equipment, are deeply integrated into various stages of automotive R&D and production with their exceptional precision, high efficiency, and outstanding flexibility, becoming a key force driving industry progress.

1. What is a PONC Profile Machining Center?

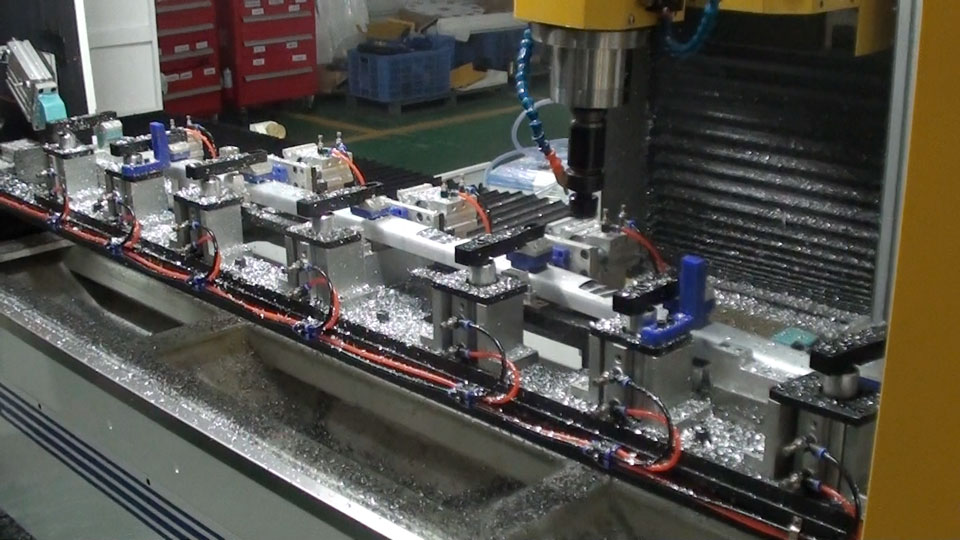

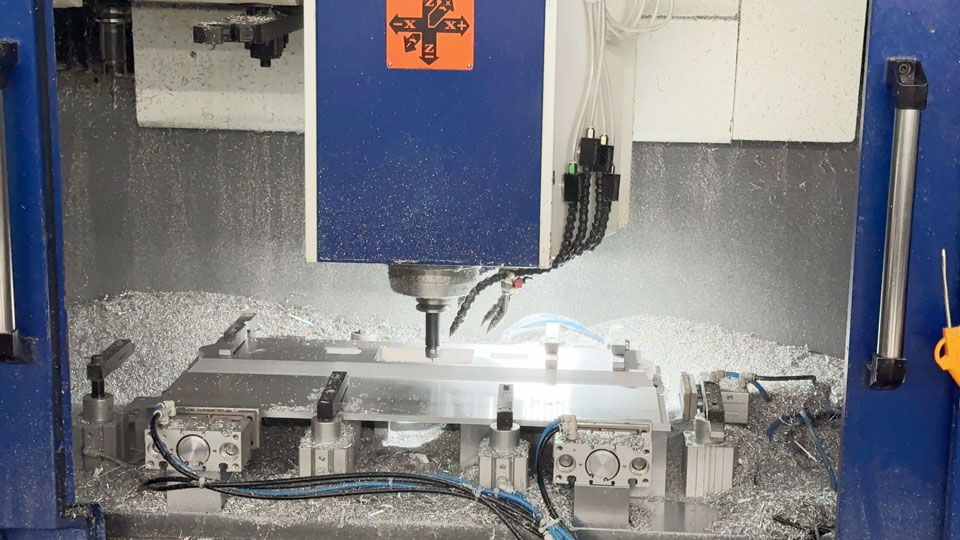

A PONC profile machining center is a CNC machine tool specifically designed for high-speed, high-precision, and multi-face machining of long-sized metal profiles with complex cross-sections (such as aluminum or steel profiles). It is typically equipped with multiple spindles, multi-turrets, an automatic tool-changing system, and a high-performance CNC system. It can complete multiple processes such as milling, drilling, tapping, and chamfering in a single setup, realizing the manufacturing philosophy of "complete machining in one clamping," significantly improving processing efficiency and product consistency.

2. Core Application Areas in the Automotive Industry

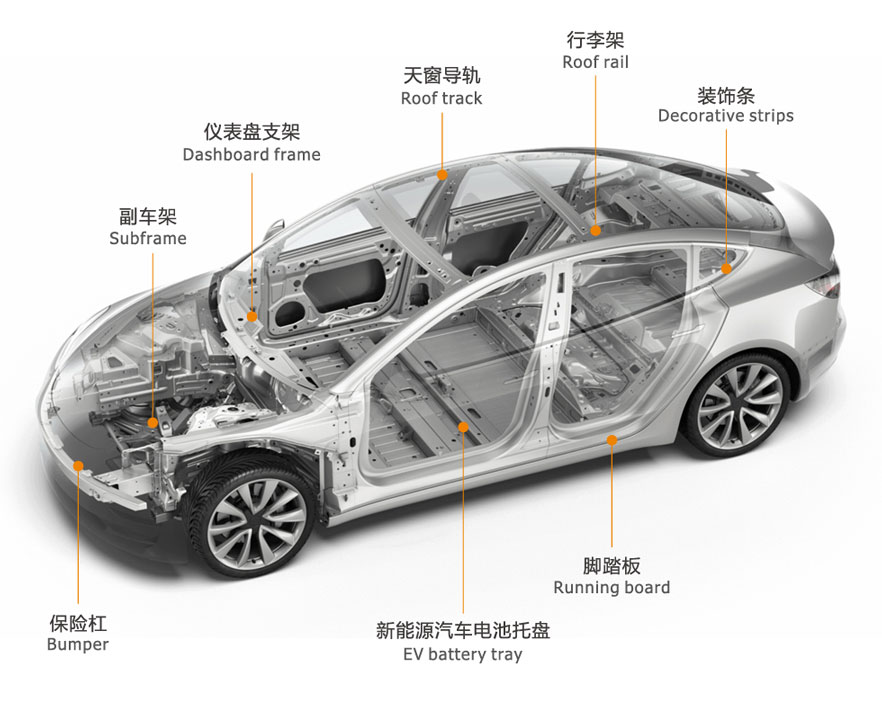

PONC profile machining centers are widely used in the manufacturing of core components, from car bodies to the "three-electric" systems.

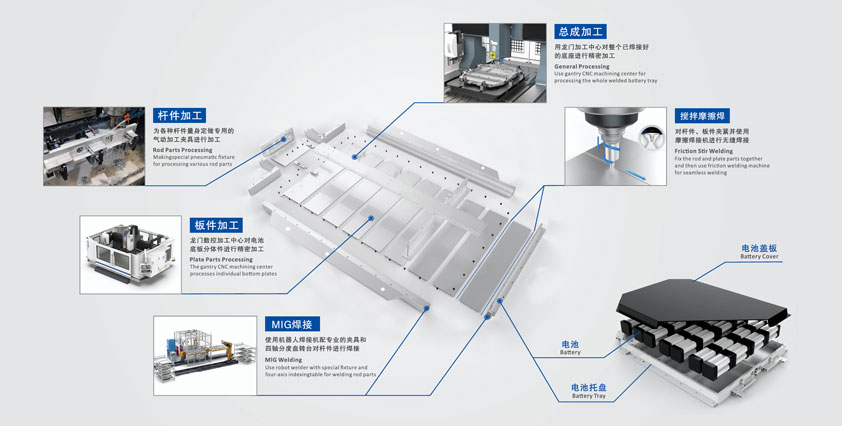

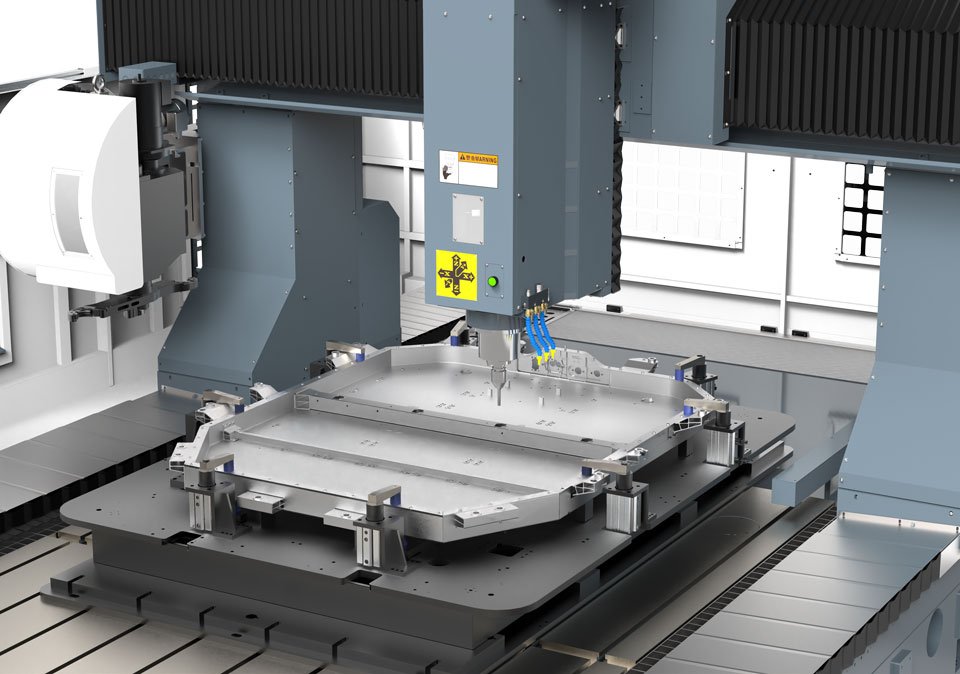

Processing of New Energy Vehicle Battery Trays (Pack Enclosures)

This is currently the most critical and prominent application. The battery tray serves as the "chassis" of new energy vehicles, and its quality directly impacts vehicle safety and range.

• High Precision Requirements: The dimensional and positional accuracy of every battery module mounting hole, wiring harness hole, and cooling channel interface on the tray must be extremely precise. Any deviation could lead to leakage, short circuits, or installation failure. PONC machining centers, with their stable high-rigidity structure and precise CNC system, can perfectly guarantee machining accuracy of ±0.02mm or even higher.

• Efficient Production: Battery trays are typically made of large aluminum profiles or extruded plates, requiring significant machining. The multi-tool simultaneous machining technology and high-speed spindles of PONC equipment can greatly reduce the production cycle per workpiece, meeting the large-scale production demands of automakers.

• Sealing Grooves and Lightweighting: The equipment can efficiently process complex sealing grooves for installing sealing strips, ensuring the battery pack’s waterproof and dustproof ratings (e.g., IP67). Meanwhile, through precise milling, non-load-bearing areas can be lightweighted while maintaining structural strength, effectively increasing vehicle range.Body Structural Components and Anti-Collision Systems

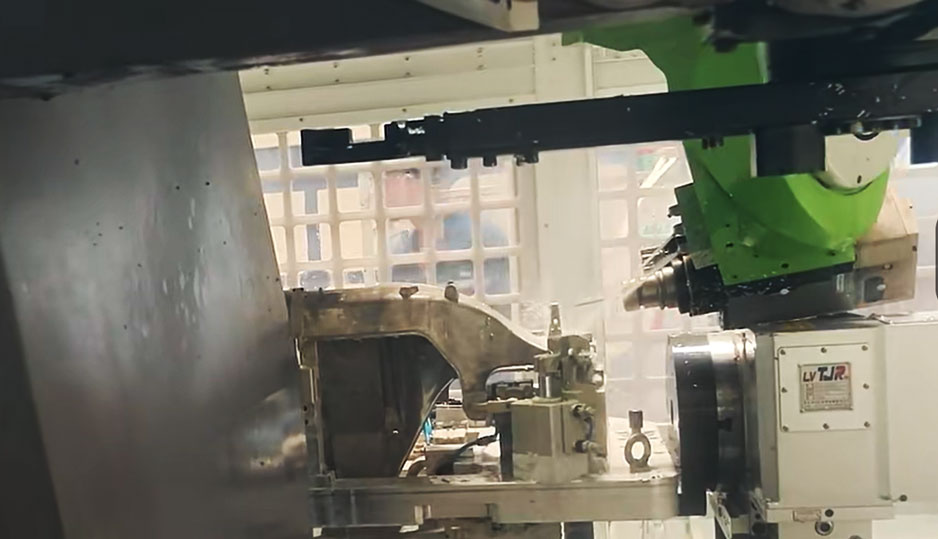

• Aluminum Underbody: In lightweight body design, aluminum profiles are widely used for structural components such as front and rear anti-collision beams, A/B/C pillars, sill beams, and longitudinal beams. These parts feature complex shapes and require high strength and crash safety. PONC machining centers can perform 3D cutting, drilling, and tapping on these high-strength aluminum profiles, providing high-quality lightweight components for body manufacturing.

• Hot-Formed Steel Parts: Although hot-formed steel is extremely hard, PONC’s high-rigidity models equipped with specific tools can also handle drilling and trimming for manufacturing safe body frames.Chassis System Components

Subframes, suspension arms, and other chassis components are increasingly made from aluminum castings or forgings, which are then precision-machined by machining centers. PONC equipment ensures these safety- and performance-critical parts exhibit high dimensional stability and assembly accuracy.Other Components and Tooling Fixtures

• Window and Door Guides: Aluminum guides for sunroofs and doors require precise profile machining and hole processing.

• Battery Module End Plates: Aluminum end plates for securing battery cells require numerous and precise positioning holes.

• Production Line and Inspection Tooling: Numerous tooling fixtures and inspection jigs on automotive production lines are also made from profiles, and their machining accuracy directly affects the quality of the main products. PONC machining centers are an ideal choice for manufacturing these "mother machine" tools.

3. How Do the Technical Advantages of PONC Profile Machining Centers Empower Automotive Manufacturing?

Ultimate Efficiency, Cost Reduction, and Productivity Improvement: Multi-spindle and multi-process simultaneous machining technology integrate processes that traditionally required multiple machines and setups into a single machine, reducing clamping time, process turnover, and floor space, significantly lowering per-unit costs.

Ultra-High Precision, Quality Assurance: High-precision guide rails, ball screws, and spindles, combined with advanced CNC systems, ensure dimensional consistency for every product in mass production, fundamentally enhancing the reliability and safety of core automotive components.

Exceptional Flexibility, Rapid Response: To meet the rapidly evolving models and demands of the automotive market, simply changing the machining program and fixtures allows the same PONC production line to quickly switch to producing different types of components, greatly enhancing manufacturing flexibility.

Automation Integration, Toward Smart Factories: PONC machining centers can be easily integrated with automated loading/unloading systems (robots/gantry manipulators), connected to AGVs and MES production management systems, becoming core units for building smart production lines and unmanned "lights-out" factories for automotive parts, enabling 24/7 efficient production.

PONC profile machining centers are no longer simple "drilling and milling" tools but modern platforms embodying the automotive industry’s pursuit of precision, efficiency, flexibility, and smart manufacturing. Especially amid the rapid development of new energy vehicles, their role in manufacturing key components like battery trays is indispensable.

With advancements in materials science (e.g., more advanced aluminum alloys, carbon fiber composites) and software technology (e.g., digital twins, adaptive machining), PONC profile machining centers will further integrate with the automotive industry, continuing to provide powerful technological momentum for manufacturing safer, lighter, and smarter cars, driving the automotive industry forward.