PONC PGME Gantry Machining Center: A High-Cost-Effectiveness Solution Driven by Volume Strategy

June 10, 2025

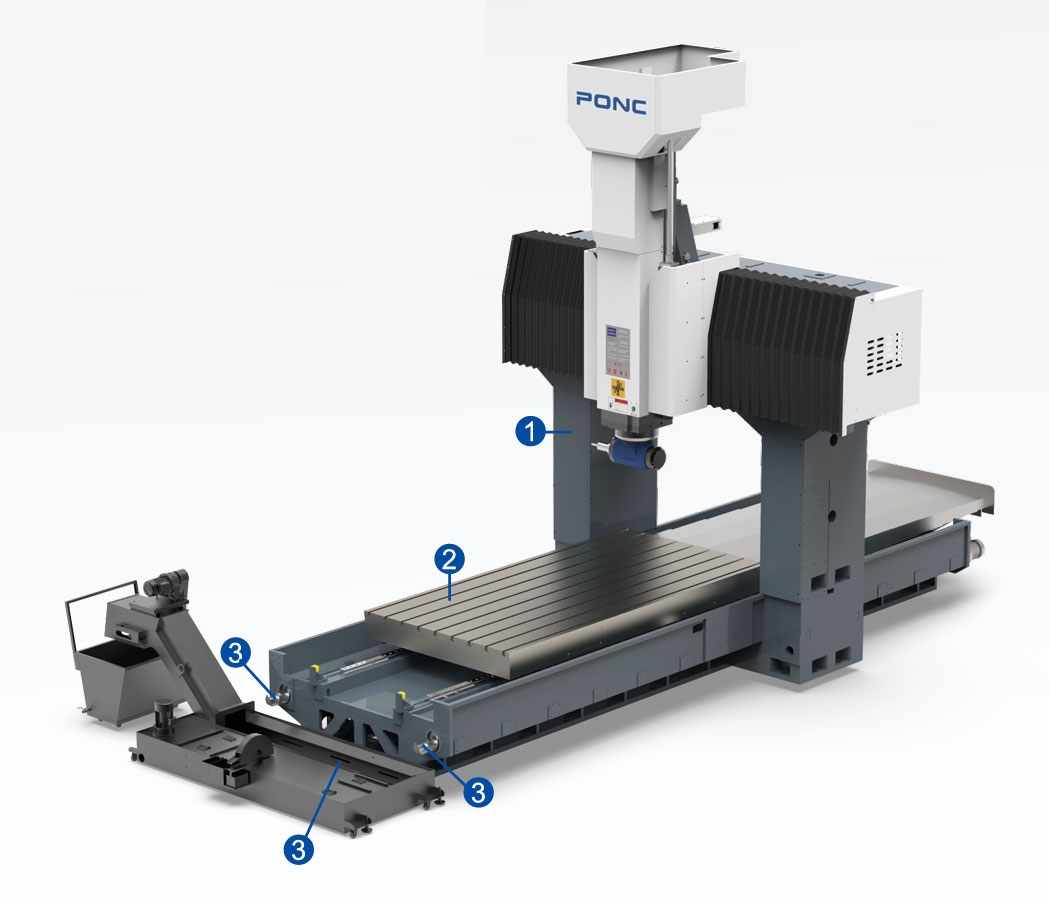

In the fiercely competitive machining industry, how do you balance equipment cost with production capacity? PONC's PGME Gantry Machining Center provides a compelling answer with its clear "volume product" positioning—delivering a stable, reliable, and powerful machining platform at an accessible price, helping companies reduce costs, improve efficiency, and rapidly scale production capacity.

PGME's core strategy directly addresses

user pain points: high cost-effectiveness for volume production. PONC

understands the manufacturing industry's demand for economical yet efficient

equipment. Through mature supply chain management, optimized mass production,

and precise cost control, the PGME series significantly lowers the entry

barrier, making it the top choice for budget-conscious users seeking to boost

capacity. It delivers gantry-level machining capabilities without requiring

massive investment.

But low price never means low

capability! PGME makes no compromises on core

features:

Smart Tool Magazine: Optional high-efficiency automatic tool magazines (e.g., 16-tool/24-tool capacity) enable automatic, rapid tool changes during machining. This drastically reduces manual intervention and downtime, especially suited for complex parts requiring multiple operations and mixed small-batch production, boosting efficiency significantly.

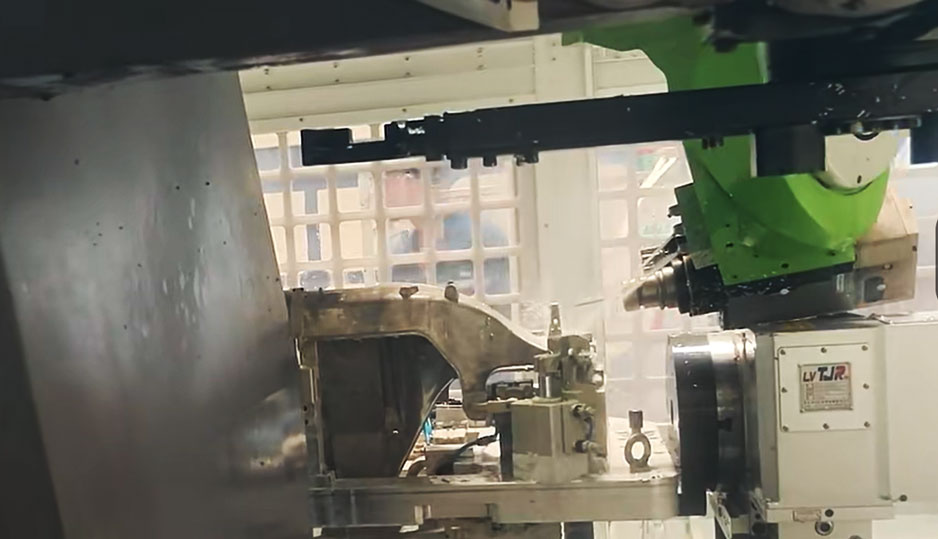

Unlimited Process Potential: The machine's robust compatibility design allows seamless integration of various universal accessory heads like right-angle heads and narrow-edge heads. Right-angle heads effortlessly handle hole patterns machining on large structures (e.g., automotive beam side holes), while narrow-edge heads reach deep into mold cavities and intricate narrow slots for precision machining. This flexibility allows the PGME to overcome spatial constraints and tackle complex machining demands for multi-surface, deep-cavity, and irregularly-shaped workpieces.

Foundation of Stability & Reliability: As PONC's volume-optimized gantry solution,the PGME inherits the brand's strict requirements for fundamental performance. Optimized structural design and reliable selection of key components ensure rigidity and precision stability during long-term heavy-duty machining, providing trustworthy production assurance.

The PONC PGME Gantry Machining Center is

precisely positioned as a "Volume Leader." It

combines the convenience of automatic tool changing, the powerful adaptability

of universal accessory heads, and reliable machining performance—all at a

highly competitive price. This equipment is the pragmatic choice for businesses

aiming to overcome budget constraints, achieve a leap in gantry-level machining

capability, and efficiently handle diverse, complex part machining challenges.

|

Model |

Table Size (W x L) |

Key Application Scenarios |

Customer Value |

|

PGME3020 |

3000×2000mm |

Large molds, engineering structures, wind

power bases |

One-stop machining for oversized

workpieces, reduces re-clamping, ensures overall

accuracy |

|

PGME2518 |

2500×1800mm |

Medium-sized housings, automotive

fixtures, injection mold bases |

Optimal balance of space &

efficiency, ideal for diversified batch

production |

|

PGME1614 |

1600×1400mm |

Precision parts, medical components,

deep-cavity small molds |

High-value entry-level gantry, compact footprint, low energy use, top choice for SMB capacity

upgrade |

Consult Now for Your Exclusive PGME

Gantry Machining Center Quote!

Contact: Email: info@ponccnc.com | Website: www.poncnc.com

Unlock a new chapter in efficient and economical machining with PONC PGME!