Deep Roots in the Gantry Domain, Forging the Benchmark in Moving-Beam Excellence

June 25, 2025

In the world of precision manufacturing,

every millimeter of precise feed and every powerful output of heavy cutting

carries the weight of industrial progress. PONC Gantry, as an outstanding brand

deeply rooted in the field of gantry machining, consistently delivers solid and

reliable power to global manufacturing with craftsmanship and innovation.

In the world of precision manufacturing,

every millimeter of precise feed and every powerful output of heavy cutting

carries the weight of industrial progress. PONC Gantry, as an outstanding brand

deeply rooted in the field of gantry machining, consistently delivers solid and

reliable power to global manufacturing with craftsmanship and innovation.

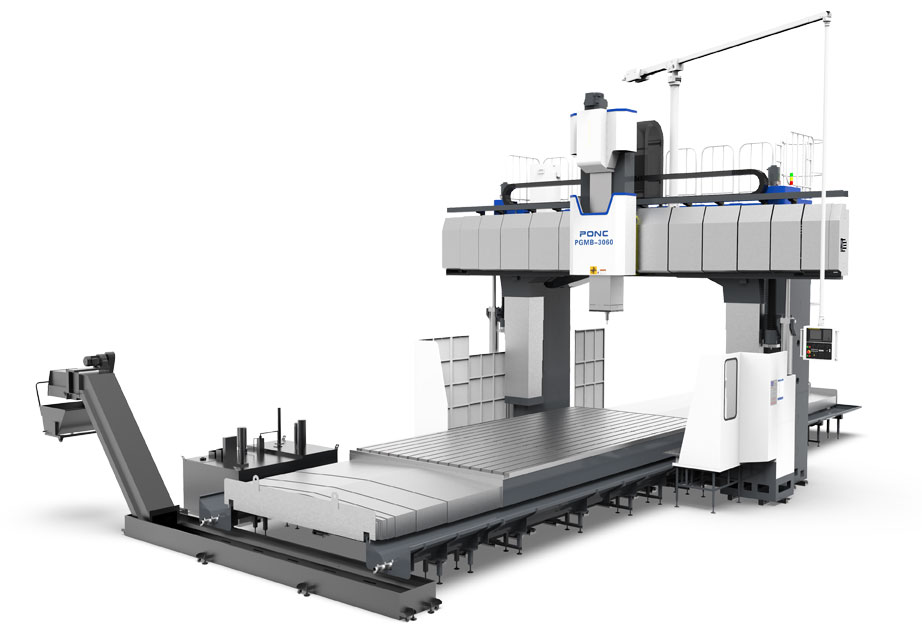

Deep Roots, Comprehensive Portfolio:

Your Gantry Machining Solution Expert

PONC understands the vast diversity of industrial needs. Leveraging our

profound understanding of gantry technology and continuous dedication, we have

built a full range of gantry machining centers with multiple specifications.

Whether it's a compact fixed-beam gantry, a highly efficient and flexible

bridge-type gantry, or a heavy-duty gantry for oversized and overweight

workpieces, PONC provides tailor-made solutions. We are not just equipment

manufacturers; we are your strategic partners in efficient production.

Dominating the Moving-Beam Realm: Core

Technology Setting Industry Standards

On the crown of gantry machining, moving-beam gantry technology shines with

unique brilliance. PONC regards this domain as a core technological high ground

and invests significant resources for continuous breakthroughs. Our moving-beam

gantry machining centers have earned high recognition in the industry for their

exceptional rigidity, extraordinary dynamic response, and top-tier precision

stability.

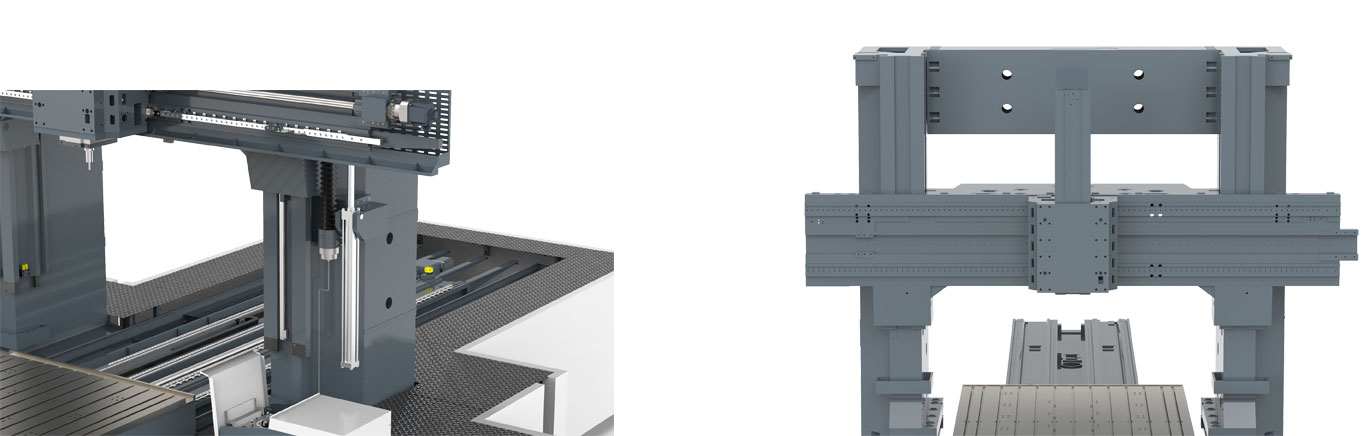

- Ultimate Stability: Innovative

structural design and top-tier manufacturing processes ensure the moving

beam remains as solid as a rock even under high-speed, heavy-load

conditions, laying the foundation for high-precision machining.

- Efficient Agility: The

moving-beam design optimizes machining space utilization. Combined with

high-speed drive systems, it significantly boosts machining efficiency,

making it especially suitable for rapid production of multi-variety,

small-to-medium batch sizes, and large complex parts.

- Precision & Reliability: Core components are meticulously selected from world-leading brands. Integrated with PONC's proprietary thermal compensation and precision control technologies, they ensure micron-level machining accuracy during long-term operation, guaranteeing every product withstands the most stringent inspections.

PONC's technological accumulation and

leading edge in the moving-beam gantry field are not achieved overnight. They

stem from our relentless pursuit of technological limits and deep understanding

of customer value. Our sustained leadership in this domain is a key reason

customers choose PONC.

The Trusted Choice, Acclaimed by Users:

Witnessed by Global Customers

Having market challenges, the reliable quality and exceptional performance of

PONC Gantry have earned the long-term trust and deep cooperation of numerous

leading enterprises across industries. From precision core components in

aerospace and energy equipment to large structural parts in mold manufacturing

and rail transportation, PONC's gantry machining centers serve as the

"cornerstone" on our customers' production lines, renowned for their

outstanding machining capabilities, extremely low failure rates, and robust

durability. This profound trust stems from our unwavering commitment: We

deliver not just a machine, but a solid guarantee of quality, efficiency, and

long-term value.