Ponc PCB5D Profile Machining Center: Single-Arm Beam Structure Elevates Five-Axis High-Efficiency Machining

May 22, 2025

In the field of high-end equipment

manufacturing, the performance of machining equipment directly impacts product

precision, efficiency, and the ability to achieve complex processes. The PONC

PCB5D Profile Machining Center, with its innovative single-arm beam structure

and five-axis simultaneous machining capabilities, sets a new benchmark for

processing aluminum profiles, precision components, and complex structural

parts. It demonstrates exceptional advantages in multi-surface machining of

large-scale workpieces.

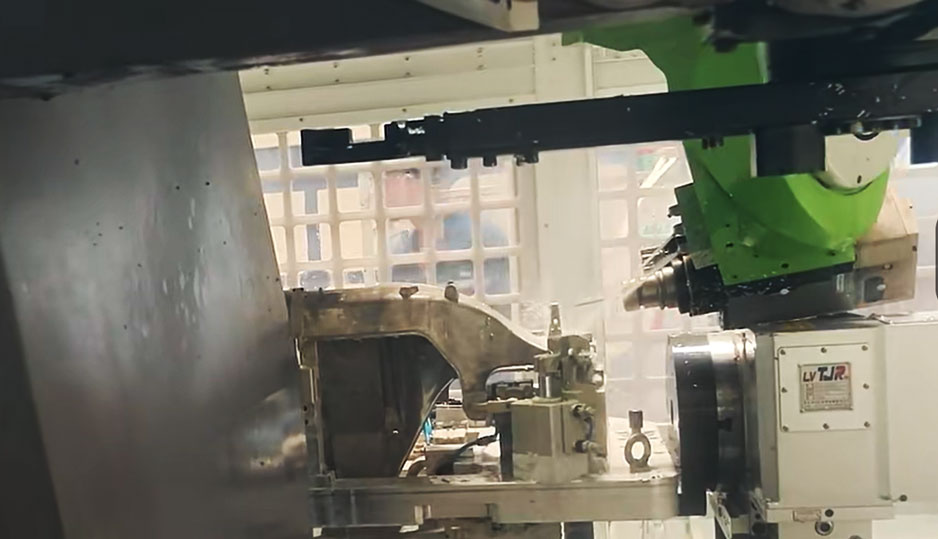

I. Single-Arm Beam Structure: Breaking Traditional Limits, Unleashing Y-Axis

Potential

Traditional profile machining centers are

constrained by frame dimensions, often limiting the Y-axis travel required for

ultra-wide workpieces. The PCB5D adopts a single-arm beam design,

optimizing mechanical layout to ensure rigidity while significantly expanding

Y-axis travel.

- Extended Machining Range: The

single-arm structure minimizes mechanical interference, enabling broader

Y-axis coverage—ideal for processing wide plates, large aerospace

frameworks, and oversized profiles.

- Enhanced Dynamic Performance: Lightweight beam design paired with high-precision linear guides ensures stability during high-speed operations, balancing efficiency and accuracy.

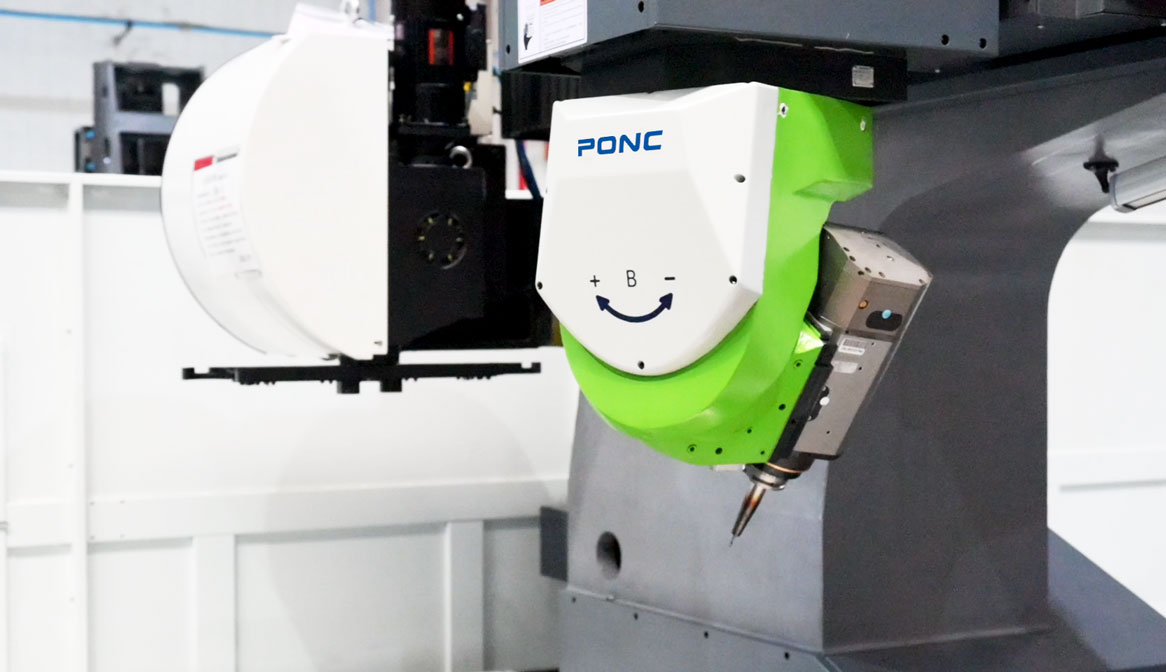

II. Integrated Five-Axis Machining:

Five-Sided Processing in Once Clamping

The PCB5D’s core strength lies in its flexible

multi-axis capabilities. Equipped with a five-axis machining head, the system

enables multi-angle machining of complex surfaces, eliminating the need for

repetitive repositioning inherent in traditional three-axis machines.

- One-Step Complex Processing: The five-axis head performs milling, drilling, tapping, and other operations on a workpiece’s front, side, top, and inclined surfaces in once clamping , reducing repositioning errors and improving consistency.

- High-Value-Added Part Compatibility:

Five-axis technology achieves precise spatial surface machining,

streamlining production workflows.

III. Technical Highlights & Applications

- High-Efficiency Flexible Production

The PCB5D integrates automatic tool changers and multi-station fixtures. Combined with its extended Y-axis travel and five-axis head, it enables rapid task switching for small-batch, high-variability production. - Industry Applications

- New Energy Vehicles: Efficient

machining of battery tray beams, plates, bumpers, and roof racks.

- Rail Transit: Integrated forming

of large aluminum alloy vehicle frames.

- Aerospace: Precision multi-surface

machining of structural components.

IV. Market Value & User Benefits

By merging single-arm beam design with

5-axis simultaneous machining, the PCB5D delivers an optimal solution

for "large-sized + high-complexity" machining:

- Reduced Clamping Time: 5-sided

machining reduces auxiliary time by over 30%.

- Improved Material Utilization:

Precision processing reduces scrap rate, ideal for high-cost materials.

- Expanded Capabilities: Enables handling of non-standard

geometries, enhancing market competitiveness.

As manufacturing advances toward high-efficiency

and ultra-precision, the PONC PCB5D redefines the boundaries of

large-scale, complex parts machining. Its single-arm beam’s unrestricted

spatial maneuverability and five-axis simultaneous machining capabilities not

only meet current demands for large-format component production but also establish

a future-ready platform for intelligent machining ecosystems.