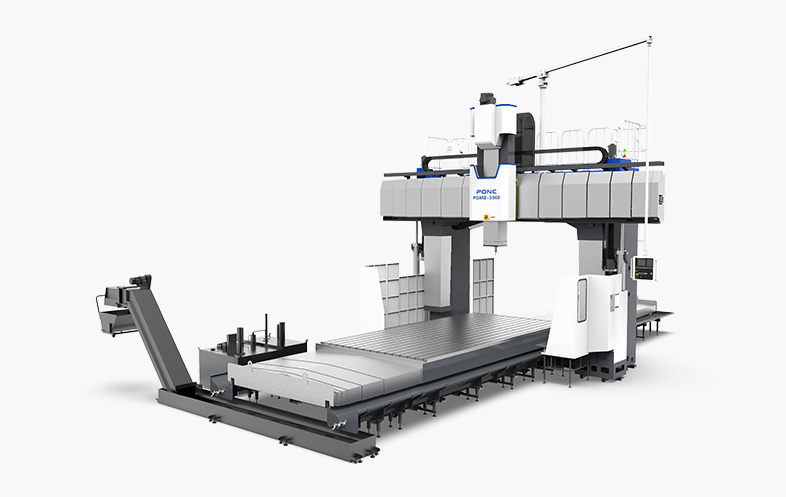

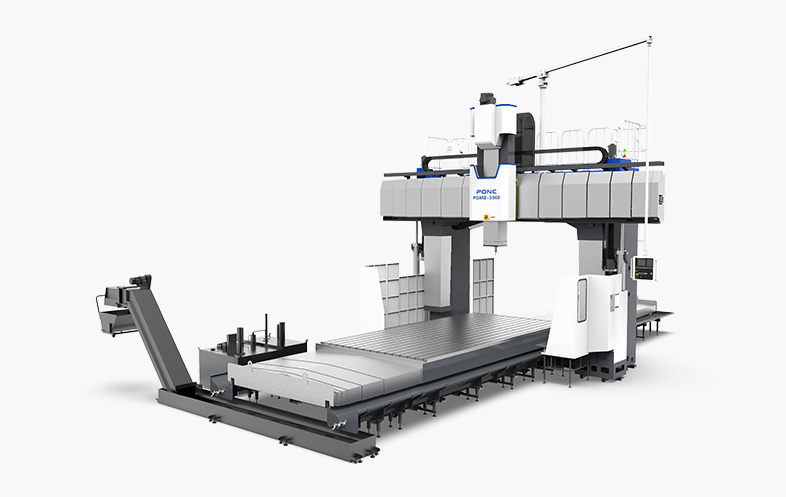

PGMB Series Bridge Type Milling Machine

| Max. spindle speed | 4500 rpm |

| Max. spindle power | 33 kW |

| Moving speed | 10/15/10 m/min |

| X-axis stroke | 4200/6200/8500 mm |

| Y-axis stroke | 4500 mm |

| Z-axis stroke | 1200 mm |

* Other lengths can be customized

| Max. spindle speed | 4500 rpm |

| Max. spindle power | 33 kW |

| Moving speed | 10/15/10 m/min |

| X-axis stroke | 4200/6200/8500 mm |

| Y-axis stroke | 4500 mm |

| Z-axis stroke | 1200 mm |

* Other lengths can be customized

| Machine Parameter - PGMB-3040/60/80 | ||

| TRAVELS | unit | Parameter |

|---|---|---|

| X-Axis | mm | 4200/6200/8500 |

| Y-Axis | mm | 4500 |

| Z-Axis | mm | 1200 |

| W-Axis | mm | 1300 |

| Distance from spindle nose to worktable | mm | 0~2350 |

| Distance between columns | mm | 3700 |

| WORKTABLE | ||

| Size of worktable | mm | 3000×4000/6000/8000 |

| Max.load | t | 24/36/48 |

| T-slots specification | / | 28×200×13 |

| SPINDLE | ||

| Spindle speed | rpm | 4500 |

| Spindle power | kW | 22/33(S1/S6-40%) |

| Spindle torque | N·m | 1076/1614(S1/S6-40%) |

| Spindle torque | / | BT50 |

| Cross section of ram | mm | 400×400 |

| TOOL MAGAZINE (OPTIONAL) | ||

| Max. capacity of tool magazine | pcs | 40/60 |

| Max. tool diameter (fully loaded) | mm | Ф125 |

| Max. tool diameter (empty loaded) | mm | Ф250 |

| Max. tool length | mm | 400 |

| Max. tool weight | kg | 25 |

| AXIS FEED RATES | ||

| Rapid on X/Y/Z | m/min | 10/15/10 |

| Cutting feed rate X/Y/Z | m/min | 6/6/6 |

| PRECISION | ||

| X-Axis Positioning accuracy | mm | 0.035/0.04/0.045 |

| X-Axis Repeatability accuracy | mm | 0.015/0.025/0.035 |

| Y;Z-Axis Positioning accuracy | mm | Y:0.04;Z:0.018;W:0.015 |

| Y; Z-Axis Repeatability accuracy | mm | Y:0.025;Z:0.012;W:0.01 |

| MECHANICAL SPECIFICATION | ||

| Required pneumatic pressure | kg/cm² | 6 |

| cnc system | / | SIEMENS/FANUC |

| Machine height | mm | 8000 |

| Floor area | mm | 12000/16000/20000×8500 |

| Machine weight | T | 80/90/100 |

1.The machine integrates functions of milling, boring, drilling (drilling, expanding,reaming),tapping.

2.The international CNC numerical control system is adopted.

3.It is suitable for processing oflarge parts, plate parts, disc parts, shell partsmolds and other precision parts.

4.Features of high precision, high speed, high flexibility and environmental protection.

5.Compared with the fixed-beam machine, the height range of the workpiece islarger, and the W-axis stroke and Z-axis stroke can be superimposed, which caneffectively prevent the ram from extending too long and affect the machiningrigidity.

6.It is widely used in theindustries ofshipbuilding, power generation, heavymachinery, locomotive,aerospace, textile machinery, printing machinery, moldmanufacturing,etc.