Profile Processing Center Manufacturer

November 11, 2025

In the lifeblood of industrial manufacturing, profiles serve as the critical framework for building curtain walls, rail transit, new energy, engineering machinery, and other fields. Their processing precision and efficiency directly determine the quality and performance of the final products. Behind this, the profile machining center, as the core working mother machine, plays a vital role. In the fiercely competitive equipment manufacturing sector, one name is consistently associated with "high precision, high efficiency, and high flexibility" – PONC, which has established its position as an industry benchmark through strength.

Deep Cultivation in the Industry, Defining New Standards for Profile Machining

Since its establishment, PONC has focused specifically on the field of profile machining, rather than broadly covering all types of machine tools. This focus has enabled it to gain deep insights into the machining characteristics of different materials like aluminum profiles, steel profiles, and composite materials, as well as the personalized needs from downstream industries such as aluminum curtain walls, automotive parts, photovoltaic brackets, and medical devices.

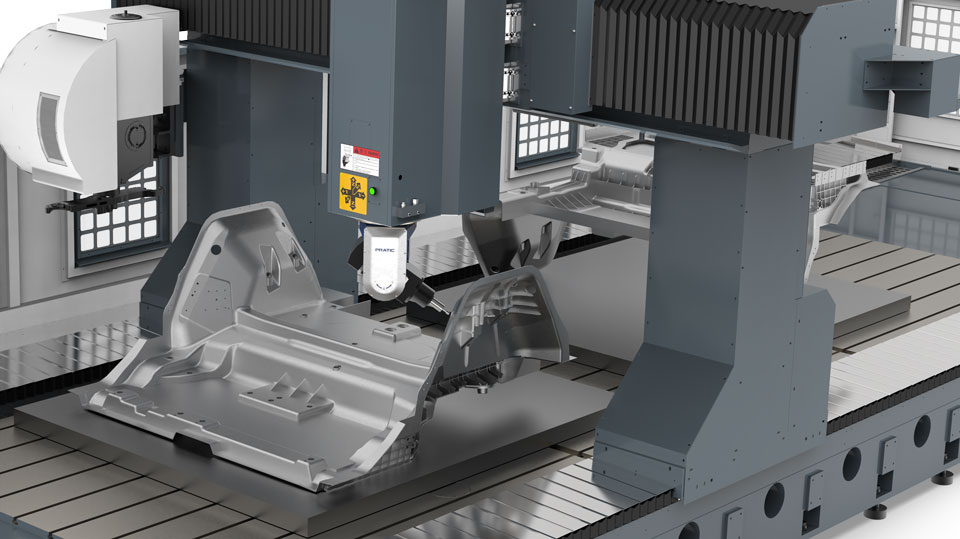

Based on this profound industry understanding, PONC's product line has evolved from initial three-axis machining centers to the current mature, diverse, and full-range profile machining solutions, including five-axis simultaneous machining, gantry-type, and CNC drilling and milling centers. What PONC defines is not just equipment parameters, but an efficient production model of "complete multiple machining processes in a single setup," significantly reducing workpiece transfer time and improving both machining precision and overall production efficiency.

Technological Leadership: The Cornerstone of Core Competitiveness

PONC's industry leadership is no accident; it is rooted in the relentless pursuit and solid accumulation of technological innovation.

1. Powerful Five-Axis Technology:This is the shining jewel in PONC's technological crown. Its five-axis profile machining centers enable one-time precision machining of complex curved surfaces and special-shaped profiles, solving the cumulative error problems associated with multiple setups in traditional equipment. Whether for the lightweight machining of new energy vehicle battery trays or special components in the aerospace field, PONC's five-axis technology demonstrates its strong adaptability and precision.

2. High Rigidity Structure and Stability: The long-term accuracy of a machine tool stems from the rigidity of its basic structure. PONC uses high-quality castings, optimizes the structure through finite element analysis, and designs high-rigidity bed and gantry frames, ensuring stability and accuracy retention under long-term heavy-load machining, with a lifespan far exceeding the industry average.

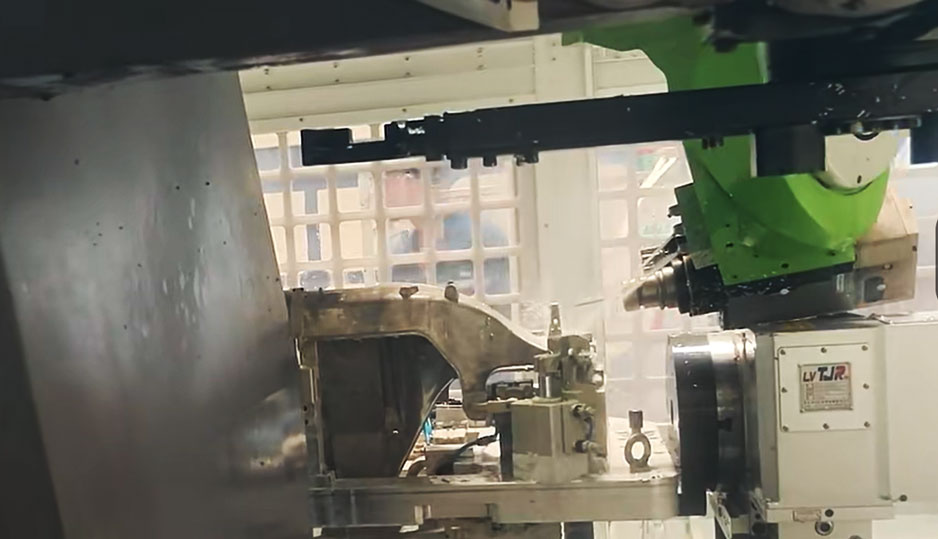

3. Intelligence and Automation Integration:PONC has long been laying out its intelligent strategy. Its equipment can be easily integrated with automatic loading/unloading systems, robot units, and intelligent material warehouses to build unmanned or minimally manned flexible production lines. Through its self-developed CNC system and MES production management system, it enables real-time monitoring, analysis, and optimization of machining data, providing a solid equipment foundation for customers to create true "lights-out factories."

4. Professional Process Software Support: PONC deeply understands the importance of "integrating hardware and software." Its dedicated programming software simplifies the programming process for complex workpieces, significantly improves programming efficiency, and effectively avoids machining interference, maximizing the equipment's technical potential.

Industry Status: The Leap from Participant to Leader

Relying on its strong technical capabilities and reliable product quality, PONC has stood out in the fierce market competition and established its undisputed industry position.

Leading Market Share: In the domestic profile machining center market, PONC's brand recognition and market share have consistently ranked at the forefront for years. Its products not only cover the whole country but are also exported to dozens of countries and regions globally, including Europe, North America, and Southeast Asia, becoming a bright business card for "Intelligent Manufacturing in China" on the international stage.

Benchmark Projects Worldwide:From globally renowned aluminum profile companies to top new energy vehicle manufacturers; from national-level rail transit projects to energy storage liquid cooling and humanoid robots, PONC's equipment operates stably in numerous key industries, making it a trusted partner for customers.

Standard Setter for the Industry: With its expanding influence, PONC has, to some extent, become a benchmark for profile machining processes and efficiency. The technical indicators and machining models achieved by its equipment are constantly being studied and emulated by peers, imperceptibly driving the improvement of the entire industry's technical level.

PONC's success lies not only in manufacturing and selling equipment but also in providing customer-centric overall solutions. We delve into customers' production sites, understand their process pain points, and tailor the most economical and efficient machining solutions, truly helping customers enhance their competitiveness and achieve win-win results.