Box in box five axis gantry sets sail overseas, helping the mold manufacturing industry

August 27, 2024

CHAPTER. 01

Departing overseas

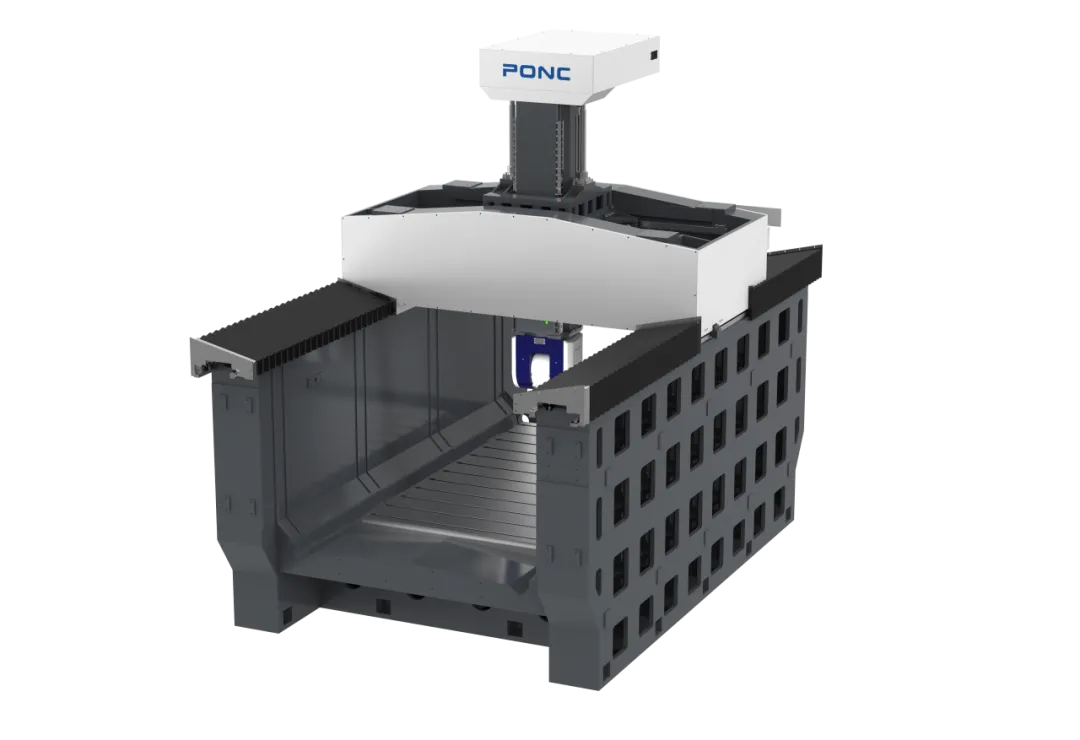

Recently, PONC high-end five axis gantry PHC5D held an equipment shipping ceremony, which will soon cross the ocean to assist customers in the overseas mold manufacturing field.

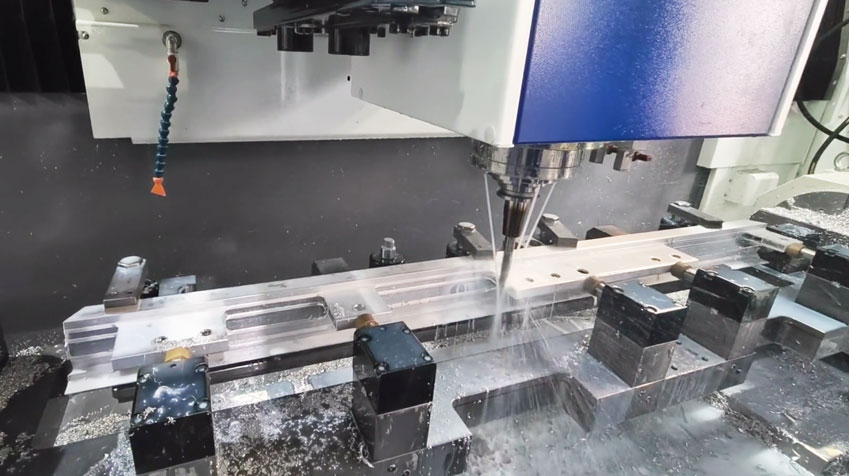

PHC5D is a gantry designed and manufactured specifically for the mold industry, which can achieve five axis linkage machining. It is particularly suitable for the precision machining needs of medium and large steel, aluminum alloys, and composite materials. This type of machining requires high machining efficiency, high surface machining quality, and accuracy. The machined surface is complex, such as inner and outer circles, conical surfaces, spherical surfaces, 2D and 3D complex curved surfaces, and multi-faceted machining.

CHAPTER. 02

Stable rigidity, efficient processing

·PHC5D adopts an integrated U-shaped casting bed worktable, with the crossbeam moving on both sides of the wall. The lightweight of the moving part facilitates the machine tool to achieve high-speed feed, matching the machining requirements of medium cutting depth, high speed, and fast feed.

CHAPTER. 03

Customized configuration to meet diverse needs

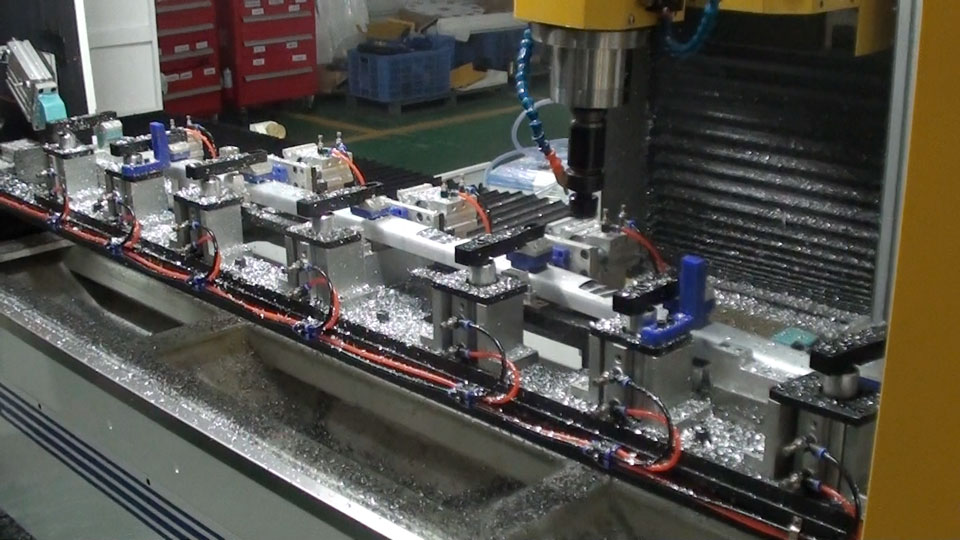

The PHC5D series is divided into linear motor models and three-axis screw models. The XY axes of the linear motor model are all driven by linear motors, with a maximum feed rate of 60m/min and a maximum acceleration of 0.3g for the three axes, which can meet higher machining requirements.

The A-axis of PHC5D can achieve a large range of ±105° swing angle, which can flexibly process complex shape and structural parts of the mold, reducing the process flow in the large mold processing.