A Powerful Tool for Long Workpiece Processing and Mass Production

February 12, 2025

Profile Processing Center: A Powerful Tool for Long Workpiece Processing and Mass Production

The PONC Profile Processing Center, as a leading processing equipment in the industry, has set a benchmark in the fields of

long workpiece processing and mass production with its exceptional performance and high production efficiency. Its unique

design and advanced technology provide users with an unprecedented processing experience and economic benefits.

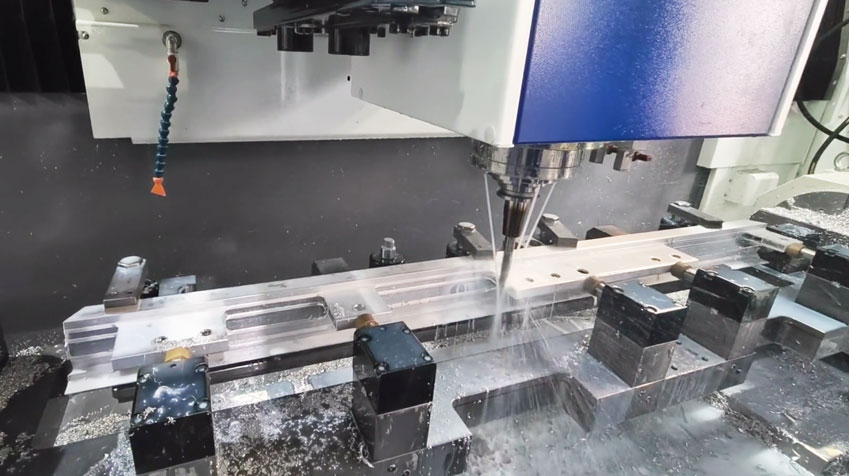

I. Effortless Long Workpiece Processing

The PONC Profile Processing Center is specifically optimized for long workpiece processing, offering the following advantages:

Extra-Long Travel: The PONC Profile Processing Center provides various bed lengths, capable of handling workpieces up to

several tens of meters, easily accommodating large-scale workpieces.

Rigid Bed: The high-strength cast iron bed, precision-machined and aged, ensures stability and accuracy even under

prolonged high-load operations.

Efficient Chip Removal: Equipped with a high-flow cooling system and chain chip conveyor, it effectively resolves chip

removal issues, ensuring smooth processing and providing strong support for automated operations.

II. Unmatched Processing Efficiency

The PONC Profile Processing Center is dedicated to improving processing efficiency, creating greater value for users:

High-Speed Spindle: Featuring a high-speed, high-torque spindle, it enables rapid cutting, significantly reducing

processing time.

Fast Movement: Utilizing high-precision linear guides and servo drive systems, it achieves rapid axis movement with

0.7G acceleration, minimizing idle travel time.

Automatic Tool Change: Equipped with a large-capacity tool magazine and quick tool change device, it enables

automatic tool changes, further enhancing processing efficiency.

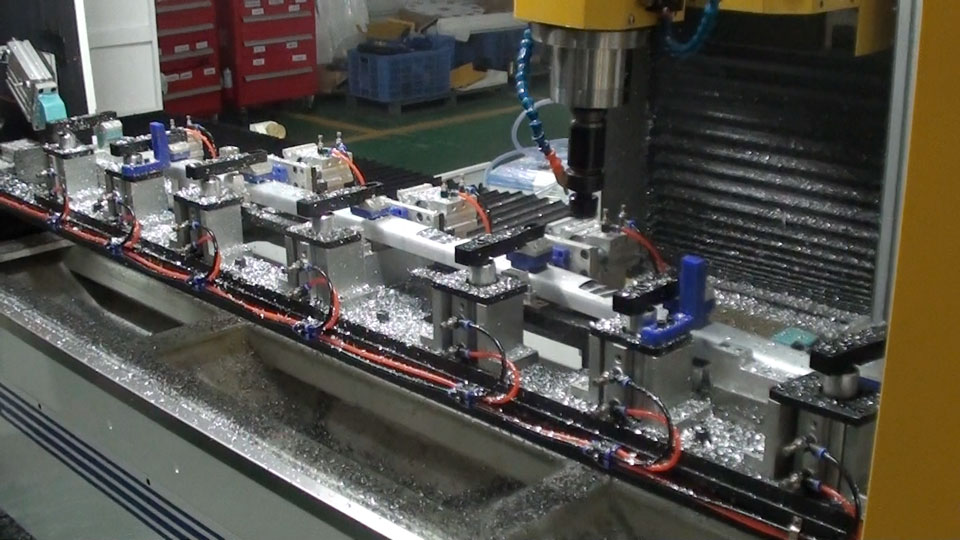

III. Seamless Mass Production

The PONC Profile Processing Center is tailor-made for mass production, offering the following features:

High Precision: With advanced CNC systems and precision transmission mechanisms, it ensures processing accuracy

and consistency, meeting the high-quality demands of batch production.

High Stability: Rigorous quality control and reliability testing ensure long-term stable operation, reducing failure rates

and guaranteeing smooth production.

High Automation: It can be equipped with automatic loading/unloading devices and workpiece detection systems,

enabling automated production, reducing manual intervention, and improving production efficiency.

IV. Wide Applications and Broad Prospects

The PONC Profile Processing Center is widely used in aerospace, rail transportation, automotive manufacturing, engineering

machinery, and other fields. It is suitable for processing various metal materials such as profiles, pipes, and rods, providing

users with efficient, precise, and reliable processing solutions.

With its outstanding performance in long workpiece processing, processing efficiency, and batch production, the PONC

Profile Processing Center has become the preferred equipment for many large enterprises. Its advanced technology and

reliable performance will help users enhance production efficiency, reduce costs, and gain a competitive edge in the

market. With a customer-centric service approach and rapid response to customer needs, Puenke offers one-stop

services, earning a strong reputation among clients.